The equipment a tissue manufacturer chooses largely dictates production performance and end product quality. Running machines that are incompatible, inefficient, or technologically obsolete can interfere with overall equipment effectiveness (OEE), competitive advantage, and the bottom line.

Körber Business Area Tissue has long been the global supplier of the most trusted equipment brands in the tissue industry. Longevity of Körber machines in the field speaks to a heritage of reliability. A revolutionary market approach to technological integration and value chain streamlining signals a future of innovation that has moved Körber from equipment provider to full strategic partner.

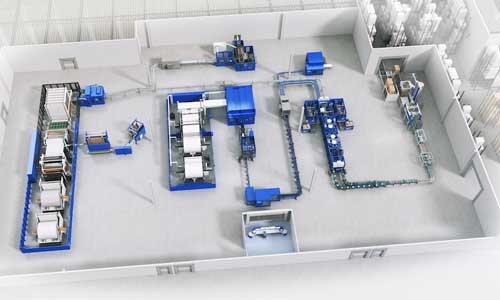

At the center of the transition is the Körber ecosystem, which consolidates technologies developed by the Körber Group and highly qualified external partners into a single solution. All technologies involved in tissue converting environments — from raw paper to finished products and distribution logistics — are accounted for and connected within the Körber ecosystem, making it a powerful “one-stop shop” for tissue manufacturers.

Simplifying tissue converting and packaging practices

An overarching goal of the Körber ecosystem is simplification. All the machines making up the production line, from parent reel unwinding to palletization, including those developed by companies external to the Körber Group, are connected to each other and controlled through Sam Flow — dedicated software that continually monitors the process and auto-regulates the main production parameters to deliver maximum efficiency for the desired finished product characteristics.

In addition to maximizing OEE, the Körber ecosystem’s single contact point offers customers:

- The best technology for specific market requirements

- Full support in optimizing line layout and minimizing industrial footprint

- Improved management of production time and costs

Experience the Körber Ecosystem at iT’s Tissue 2022

The Körber ecosystem helps foster secure partnerships between Körber and tissue converters. Long-term strategies provide added focus on long-term objectives, flexibility in day-to-day problem-solving, and the ability to capture new growth opportunities. It’s a revolutionary market approach that’s changing the tissue industry, and you have an opportunity to see the Körber ecosystem operating live.

At iT’s Tissue 2022, the Körber open house will showcase a tangible example of how integrated and connected machinery dialogue with each other to obtain maximum production efficiency. An array of Körber equipment will be on display, including:

- The new Perini Vega S8 lines for converting large-diameter rolls typical of away-from-home products

- The new MTC ITF Change line for interfolded products featuring an automatic and quick change cut-off format

- The new Casmatic Zephyrus packaging machine for sustainable and e-commerce ready mixed formats with both roll and folded products packed together

- The latest systems of the Sam Operational Solution family that help prevent the risk of quality non-conformities in finished products;

- Warm-up Contactless Double, our breakthrough technology for hot embossing, now available for heating both engraving rolls;

- The PA15, an innovative, fast and flexible palletizing solution developed by the Körber Business Area Supply Chain

- Our portfolio of digital solutions for the tissue industry including Tissue manufacturing operations management (TMOM) by Körber and Boost by FactoryPal

The Körber ecosystem is a shining example of how innovation, technology, and machinery work together to advance the tissue industry.