2020 will be remembered as unexpected and transformational. As we reach the end of it, we take time to look back at some of the important milestones that were achieved and key decisions that were made, and we reveal our expectations and predictions for the year ahead.

Throughout the pandemic, our key priorities have been caring for our employees, ensuring business continuity for our customers, and accelerating decisions to build a better future for all our customers. Adapting to the circumstances, we deployed live streaming demonstrations from our Competence Centers, providing an immersive experience to discover the latest printing and converting technologies. We also hosted several webinars during the year to keep our customers informed on our new solutions and share our industry experience.

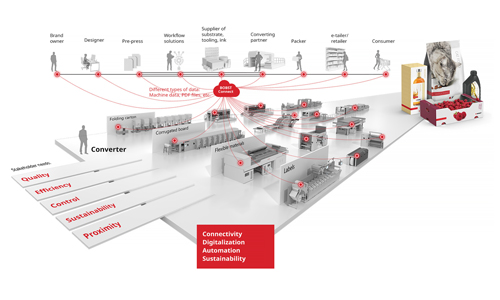

Brand owners face increased competition and pressures around shorter times to market, smaller lots sizes, optimal protection and color consistency. These factors, along with the rise of smaller companies, associated with new business models including e-commerce, and the need to fulfil sustainability commitments, are leading the packaging industry into a profound transformation.

It is therefore an opportunity to drive more agility and sustainability. In spring 2020, BOBST announced a new industry vision aimed at connecting all packaging stakeholders throughout a new value chain to enable quality, efficiency, control, sustainability and proximity.

This vision, shaping the future of the packaging world, is based on four pillars: Connectivity, Digitalization, Automation and Sustainability. Within the vision we announced BOBST Connect, our software-based offering for digitalizing and connecting all products.

The vision is now becoming reality with new products & solutions and with a new company structure to be even more customer centric, less complex, and more agile, delivering more innovations. The new company structure can also rely on three new revamped industrial sites which will help our employees to enjoy better working conditions and our customers to come and see our innovations. The sites are San Giorgio in Italy for flexible packaging, Lyon in France for corrugated board and Itatiba in Brazil for our local production of folding carton solutions.

Folding Carton and Corrugated Board

In 2020, the folding carton and corrugated board industries were marked by an overall acceleration in e-commerce due to global online retail growth, where quality, waste reduction and goods protection are fundamentals. For folding carton, sustainability, increasing global regulation and demand for short runs and customization also grew in importance.

For folding carton, we launched two connected products: the die-cutter MASTERCUT 106 PER and TooLink, connecting tooling with the machine. Together, these solutions enable massive reductions in setup time & costs and increase profitability for unrivaled productivity. We launched the New ACCUCHECK – an in-line solution to inspect carton blanks for defects. In short, we made zero-fault packaging in folding carton a reality. We also launched the VISIONCUT 145 PER, the latest edition of large format flatbed die-cutter, which has been a huge sales success.

We launched MASTERSTAR, the world’s fastest, most automated, most versatile and most ergonomic sheet-to-sheet laminator, suitable for both folding carton and corrugated board. We celebrated 20 years since we launched POWER REGISTER – the ‘no contact’ sheet feeding system, which was an industry-first and remains unique in its capabilities today, demonstrating that true innovations can stand the test of time.

For corrugated, we hit a milestone with our VISIONCUT 1.6 flatbed die-cutter, selling our 300th machine. We continued to invest in our portfolio and made upgrades to our machines, including the EXPERTFOLD 145-165 folder-gluer range, which can now achieve a further 20% reduction in setup time and even greater flexibility and accuracy with corrugated packaging, and the FFG 924 NT RS, to which we added a dual slotter, enabling two boxes in one print repeat, significantly increasing flexibility and productivity to up to 40,000 boxes per hour…

In summary

2020 was unexpected but it accelerated underlying trends and made decisions more obvious. It has confirmed that the industry vision we worked on is relevant and timely. Connectivity, Digitalization, Automation and Sustainability will be the four cornerstones shaping the future of the packaging world and we want to achieve this with meaningful innovations. In 2020, we celebrated our 130th anniversary with three fully revamped sites, and we deployed a new company structure with an entrepreneurial spirit to be closer to our customers.

2021 will ultimately not be very different from 2020. We will need to be resilient and at the same time we need to focus on what matters the most – meaningful innovations made to last. We will continue to deliver best in class machines and services, but with added intelligence and software capabilities to make packaging production better than ever. All our machines and new products to come will illustrate this commitment. You can count on us.