ANDRITZ has received an order from Asia Symbol (Guangdong) Paper to supply a complete tissue production line – from stock preparation to a double-width tissue machine (TM13), including automation – for energy-efficient production of high-quality grades at its mill in Jiangmen Xinhui, China. Start-up is planned for the end of 2022.

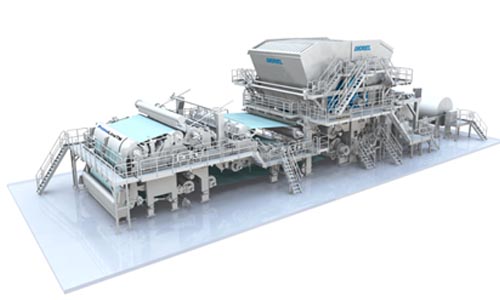

The tissue machine of the type PrimeLineTM W 2000 will have a design speed of 1,900 m/min and a width of 5.65 m for the production of paper towels, kitchen rolls, napkins, handkerchiefs, and facial tissue in the range of 11 to 42 gsm. It features a PrimePress XT Evo shoe press that dewaters the web gently, but still achieves a far higher post-press dryness than conventional presses. The line force and/or shoe tilt can be adjusted in a very flexible way in order to optimize the product quality and reduce consumption of drying energy. In addition, an 18 ft. PrimeDry Steel Yankee with a steam-heated PrimeDry Hood ST for energy- and cost- efficient drying will be installed.

The order also includes the stock preparation system with LC (low-consistency) refiners for superior fiber properties, the approach flow system with a ModuScreen HBE headbox screen for pulsation-free screening, as well as undermachine pulping.

The entire production line will be equipped with an ANDRITZ PrimeControl automation system (MCS, DCS, and QCS) which includes extended features for process automation throughout the tissue line and minimizes the number of subsystems and associated interfaces.

Steven HUNG, General Manager of Asia Symbol (Guangdong) Paper, says: “The tissue business is new to us, but we have rich experience in the production of high-quality printing and writing paper. We are used to working together with the best companies worldwide. This is why we chose ANDRITZ as our partner to enter the tissue business.”

Asia Symbol (Guangdong) Paper is part of the RGE Group, a global player that focuses on sustainable pulp and paper production.