Valmet will supply a complete tissue production line including stock preparation, automation system and a Focus rewinder to Arkhbum Tissue Group LLC. The new Advantage DCT 200 tissue line will be installed at the company’s mill in Vorsino industrial park, Kaluga region in Russia. The start-up is planned for the first quarter of 2023.

The order is included in Valmet’s orders received of the third quarter 2021. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 20-40 million.

The new tissue production line from Valmet is part of Arkhbum Tissue Group’s development project aimed at reaching a total capacity of 210 thousand tons of high-quality tissue and towel products made from own pulp.

“We are happy to receive this prestigious order and excited to continue the journey with Arkhbum Tissue Group. Our collaboration began with the supply of a Focus Reelite rewinder for their first tissue line and now we will continue with the supply of the complete line. The Advantage DCT200 is a reliable and highly efficient technology, and we are convinced it will contribute to the success of Arkhbum Tissue Group in a competitive market,” says Jan Erikson, Vice President Sales, Tissue Mills business unit, Paper business line, Valmet.

The new tissue machine TM2 will have a width of 5.6 m and a design speed of 2,000 m/min. It will add 70.000 tons a year of high-quality napkin, toilet, and towel grades to Arkhbum’s current production. The raw material to be used in the tissue production will be virgin fiber from the owner’s own pulp mill. The new production line is optimized to save energy and to enhance the quality of the final product.

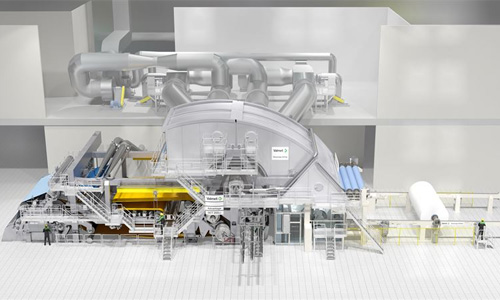

Valmet’s scope of delivery will comprise of a complete tissue production line including stock preparation systems and a Valmet Advantage DCT 200 HS tissue machine. The machine will be equipped with an OptiFlo TIS II headbox, the Advantage ViscoNip press combined with Advantage ReDry and a steel Yankee dryer. It also features other Advantage tissue technology including an AirCap Heli hood, WetDust dust system and a SoftReel, and complete clothing packages with Valmet Forming Fabric GMs, Valmet Press Felts STMs and Valmet Black Belt R ViscoNip belts. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners, Valmet DX protection screens and OptiScreen machine screens. In addition, a Focus Reelite R25 ENS rewinder as well as a roll handling system will be installed.

Furthermore, the delivery will include a Valmet DNA Automation System with process controls, machine controls and drive controls. Valmet IQ Quality Control System (QCS) with IQ Fiber sensor, MD Controls and IQ Dilution profiler with CD Control ensure high end-product quality.

Project execution services like complete engineering, shipping, installation supervision, training, start-up and commissioning are also included in the delivery.