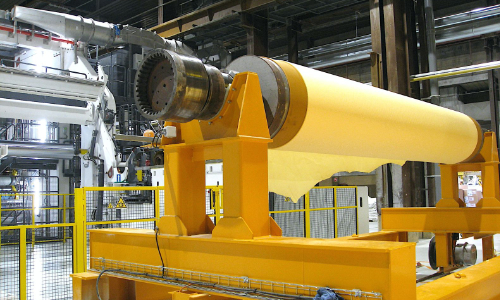

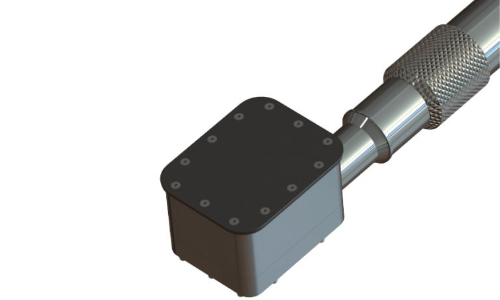

Ircon-Solaronics was selected by the Pak group / Macedonian Papel Mill MEL to improve the coat drying in their mill in Thessaloniki. The project consists by replacing an electrical infrared dryer supplied by Ircon-Solaronics more than 25 years ago by a new gas infrared UniDryer system.

For this project, Ircon-Solaronics offered solutions to reduce drastically the energy costs by:

- Changing the energy (electricity to gas): an important factor for the energy savings.

- Installing efficient emitters: The Ircon-Solaronics Gem12E emitters are the most efficient high powerful emitters on the market which results in a lower gas consumption.

- Installing the UniDryer technology: The convective part fo the UniDryer handles the mass transfer by blowing hot air coming from the emitter’s flue gases

- Reusing the hot air: the hot air evacuated from the UniDryer system will be reused as energy source for a hot air gas heated air dryer in order to reduce its energy consumption.

This kind of project has generally a return-on-investment of less than 2 years.

Ircon-Solaronics is pleased to participate in this project which confirms its position as technology leader in optimizing the drying after coating stations.

RELATED NEWS

SCA to increase NBSK price

February 13, 2026

Craig L. Nix Appointed to Sonoco Board of Directors

February 12, 2026

Sonoco Declares Regular Quarterly Common Stock Dividend

February 12, 2026

Metsä Group and ANDRITZ start up demo plant for new lignin products

February 12, 2026

Stora Enso releases climate resilience plan

February 12, 2026

TASOWHEEL : Demo Moisturizer Available for Industrial Trials

February 11, 2026

Dong Tien, Vietnam, successfully starts up its third ANDRITZ OCC line

February 10, 2026

Fibre Excellence provides an update to PaperFirst.info

February 9, 2026

Bellmer launches a new project with Fábrica de Papel da Lapa

February 9, 2026

Futura and Plusline to deliver six “Jumbo to Pallet” lines to ERUSLU

February 6, 2026

Sappi Europe announces price increase for woodfree coated sheets

February 5, 2026