Walki Westpak has made sizable investments to meet the rising demand for recyclable flexible packaging. The company is expanding its production capacity by acquiring a new printing press and constructing a new post-processing hall.

“Our customers expect short lead times and the highest print quality, even for short-run campaigns, which are often driven by fast-changing consumer trends and retail demands,” says Jonas Skuthälla, Head of Sales, Flexible Packaging.

The investment entails two parts. The first is a state-of-the-art flexographic printing line, prepared for printing with both water-based and solvent-based inks. The new line enhances both sustainability and efficiency by enabling environmentally friendly printing with less waste and energy use.

The second is a new post-processing hall, which will improve workflow and material logistics while also enhancing workplace safety by streamlining traffic and separating operational zones more effectively. The relocation of finishing operations will free up space for all printing machines to be centralised in one area, boosting overall productivity. A new prepress mounting unit is being installed, and renovation work has been made to office spaces to accommodate the changes.

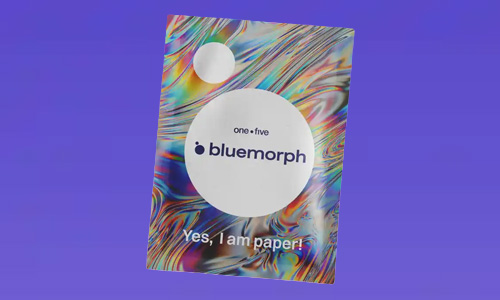

Future-proof packaging for a circular future

Recyclable flexible packaging, including lightweight monomaterial solutions for polymer-based products, is becoming increasingly important in response to new legislation, changing consumer expectations and sustainability requirements.

“This investment reflects our commitment to offering recyclable and material-efficient packaging solutions that meet the evolving demands of the market, and is a critical step in securing our future competitiveness. With these investments, we are also embracing the latest technology to help future-proof solutions for our customers”, says Sune Kapténs, Head of Production Cluster Converter.

The investment will also have a positive impact on employment in the Säkylä region, as 10 new employees have been hired to support the expanded operations.

The staff has undergone machine-specific training, and the new premises are ready to welcome orders.

“Customers are warmly welcome to visit us to see the new printing line in action”, says Kapténs.

Photo/Walki