Global paper producer Sappi has commissioned ABB’s fiber measurement technologies to enhance energy efficiency and increase productivity and profitability at its Maastricht mill in the Netherlands.

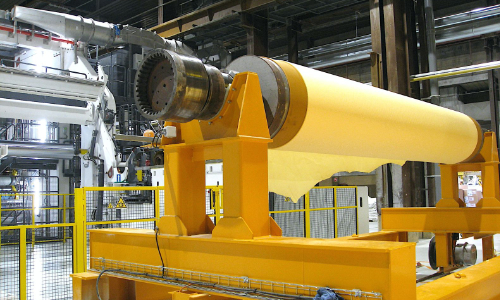

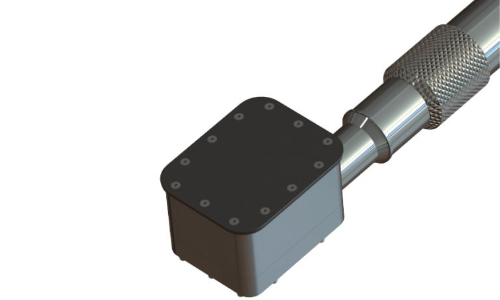

ABB’s L&W Fiber & Freeness Online is an industrial hardware solution that provides accurate and continuous fiber morphology measurement and freeness at the wet end of the paper production process. It has been deployed at the Dutch mill to stabilize pulp quality at the stock preparation, controlling and refining stage. This results in better runnability on paper, board or tissue machines, helping make more on-specification product at lower cost.

Machine operators at the mill have greater visibility into the batch process for producing microfibrillated cellulose (MFC), more accurately controlling the properties end-customers have requested. Such monitoring has consistently proven to be reliable in better predicting how the materials behave when online in the machine. This ensures high quality, on specification of the pulp mix/fibers through the wet end of the paper machine.

The mill, which has reinvented itself numerous times over the years, recently switched to the production of luxury packaging cardboard after anticipating the shrinking market for graphic paper[1]. It now includes high-end retailers, magazine publishers and packaging converters in its customer base.

“Papermakers strive for consistency at every stage of their process, predictable outcomes to meet customer specifications,” said Wilson Monteiro, Global Business Line Manager for Pulp, Paper & Fiber, ABB’s Process Industries division. “Sappi is making papers for the luxury market at Maastricht and wants to achieve the right quality, neither under nor over processed. ABB’s L&W Fiber Freeness Online is a tool to optimize this at the early stock preparation stage. We look forward to working with Sappi to understand the results of its use and support further developments.”

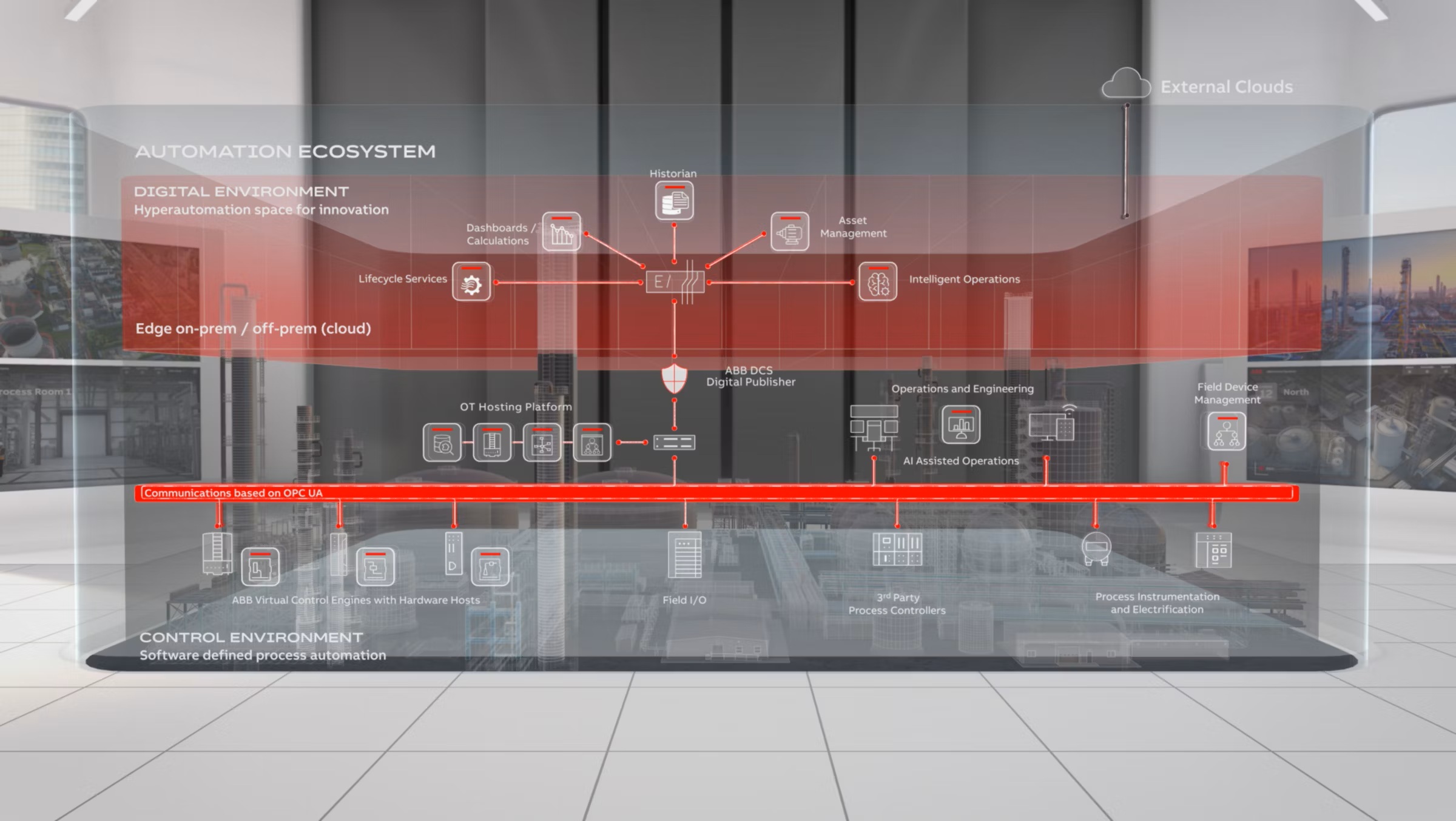

“We’re very proud of the legacy built up at Sappi Maastricht but we are also set on the future with open eyes for the innovative possibilities,” said Jeroen Janssen, Process Technologist, Sappi. “Together with ABB we are committing to the use of online fiber measurement technologies and we appreciate their expertise. It is one part of the infrastructure at the mill which has recently brought in other solutions for improved electrification, productivity and sustainability.”

Sappi Maastricht employees nearly 500 employees and produces around 260,000 tons of coated woodfree paper and paperboard per year. It is currently marking its 175thanniversary year.