Mondi, a global leader in sustainable packaging and paper, will be presenting its broad portfolio of packaging solutions for the coffee industry at HOST Milano from 17 to 21 October 2025 in Pavilion 18, Stand K59. Visitors will learn how Mondi meets the requirements of modern roasters in line with PPWR regulations through innovative packaging materials with a high barrier and excellent machine runnability.

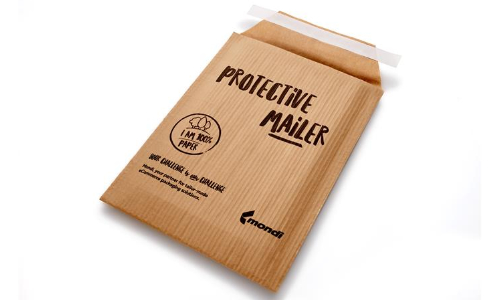

Mondi’s diverse portfolio includes sustainable primary and secondary packaging made from paper, plastic and hybrid materials that are designed for recycling. The range extends from innovative mono-material SoftPack or VacuumPack formats in polypropylen (PP) or polyethylen (PE) to paper-based StickPacks and PodSachets, offering tailored solutions for all applications from ground coffee, whole beans to coffee pods and capsules. With Ad/Vantage TrayWrap, Mondi offers a paper alternative for plastic in secondary packaging which can save over 75%[1] CO2 e and optimises customers packing process by eliminating the shrink oven. The solution is crafted from 100% kraft paper and has a unique combination of mechanical properties with very good stretchability. Ad/Vantage TrayWrap is designed for recycling, making this solution also suitable for grouped packaging applications, in line with future regulatory requirements in Europe.

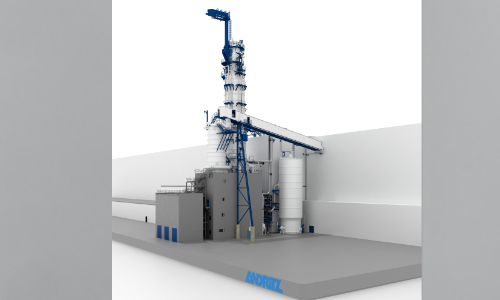

As a highlight, Mondi is presenting re/cycle VentPack, a next generation degassing concept for coffee packaging. The innovative valve, which is pre-applied to the film, aims to simplify the packaging process for customers. Thanks to its extremely thin, PP-based construction, VentPack can save up to 96 per cent in plastic weight compared to conventional button valves and is designed for recycling as a mono-PP packaging.

Mondi’s solutions offer numerous advantages for the coffee industry: high-quality barrier properties protect the coffee from exposure to oxygen and moisture for up to 12 months. Flexible printing options, such as creative flexographic and rotogravure printing processes with matt and anti-seal coatings, ensure attractive product presentation and strong shelf impact. The solutions are sustainable by design and help customers comply with EU regulation. In addition, they can be efficiently processed on existing filling lines and are supported by a Europe-wide production network that ensures security of supply.

With FlexStudios Mondi further offers customers an innovation hub in which they can actively participate in the development process, benefitting first-hand from the company’s extensive expertise and material-neutral approach, state-of-the-art technology, and customer-centric approach. By bringing pilot lines, testing capabilities and co-creation space together under one roof, Mondi can reduce time-to-market innovations, ensure compliance, and drive sustainable change in the flexible packaging industry.

[1] According to Mondi’s in-house lifecycle-based PIA (Product Impact Assessment) tool, critically reviewed by an external expert. Cradle to gate climate change impact, assuming 15g Mondi’s Ad/Vantage TrayWrap vs 11g virgin PE shrink film.