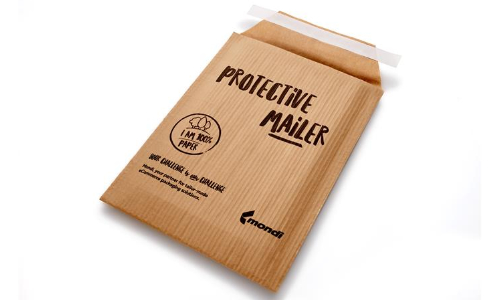

Metsä Board has completed a cradle-to-grave life cycle assessment* comparing the carbon footprints of takeaway food trays made from MetsäBoard Pro FSB Cup and fossil-based polypropylene. The study included biogenic carbon sequestration and emissions, and was verified by independent reviewers from RISE and SimaPro UK. Multiple end-of-life scenarios were assessed, including regional recycling and full incineration.

Under the European end-of-life scenario**, the carbon footprint of a takeaway food tray made of MetsäBoard Pro FSB Cup was shown to be negative for the studied life cycle – meaning that more carbon, expressed as CO₂ equivalents, was bound in the paperboard’s fibres than was released during the processes of the first life cycle. The carbon footprint of the PP tray was 0.112 kg CO2e. When the end-of-life scenario was 100% incineration, the carbon footprint of a takeaway food tray made of MetsäBoard Pro FSB Cup was 91% lower than that of a tray made of polypropylene.

The recycling rate of paperboard packaging is higher than that of plastic packaging in Europe, and recycling delays carbon release from the packaging material. According to the latest Eurostat data, 87% of paper and cardboard packaging was recycled in the EU in 2023, compared to 42% for plastic packaging***.

Both plastic and paperboard contain carbon, which forms carbon dioxide during incineration. The key difference is that paperboard’s emissions are balanced by the carbon dioxide absorbed from the atmosphere during tree growth, while fossil-based plastics add new carbon to the atmosphere.

“In addition to the biogenic carbon and high recycling rates, our paperboard benefits from the high share of fossil-free energy in production, which was 89% in 2024. Metsä Board’s target is to phase out the use of fossil energy in its mills by 2030,” says Lari Oksala, Sustainability Manager at Metsä Board. “The packaging material must always be tested and selected according to the intended application. The greatest climate benefit comes when packaging performs its core task – protecting the product.”

This study is part of a larger set of comparisons Metsä Board has been conducting to provide transparent, science‑based insights into the climate impacts of different packaging materials. “It is essential that we provide verified, science‑based data to support our customers in making informed packaging choices. Such comparisons help the market move towards solutions that reduce climate impact,” says Marjo Halonen, VP Marketing, Communications and Sustainability.”