A new recyclable solution with barrier properties, suitable for flexible packaging of frozen food products such as ice cream cones.

Lecta, a company specializing in the design and development of paper-based solutions for flexible packaging, is expanding its range of metallized papers with Metalvac Ice Cream, a paper that meets the current requirements for technical performance, industrial efficiency and sustainability in the sector.

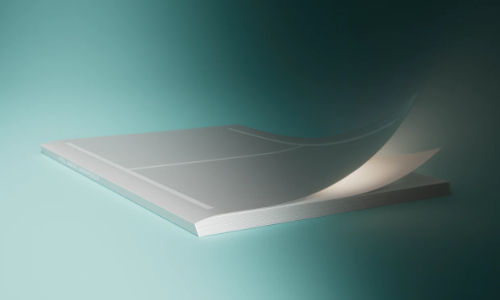

Metalvac Ice Cream is an innovative paper intended as a more sustainable alternative to existing laminate solutions on the market.

Available in 123 gsm, this new paper offers high-quality printing in offset, flexography and rotogravure on its metallized side. Its water-vapor barrier also ensures optimal preservation of wafer cones, in direct contact with the paper, throughout the supply chain.

This, along with its excellent runnability, positions Metalvac Ice Cream as a reliable and efficient solution for industry packing lines.

This new metallized paper is recyclable within the paper and cardboard recycling stream, in accordance with CEPI recyclability standards. It also aligns with circular economy principles and represents an efficient, more sustainable alternative for multiple flexible packaging applications.

The Metalvac range offers various paper grades with heat-sealability properties and barrier to light, water vapor, oxygen, and aroma, as well as resistance to moisture and grease (no PFAS added). These high‑vacuum metallized papers stand out for their excellent runnability and adaptability to standard packing lines on the market, ensuring efficiency throughout the production process.

Its low aluminum content (0.08 gsm) contributes to achieving high barrier performance without compromising the material’s recyclability within the paper recycling stream.

With the Metalvac range and the launch of Metalvac Ice Cream, Lecta reaffirms its commitment to responsible innovation and to advancing toward a more sustainable future for the flexible packaging sector.

The entire Metalvac range is produced following Good Manufacturing Practices (GMP) and Food Safety (FSSC 22000) standards, in compliance with environmental management standards ISO 14001 and EMAS, energy efficiency ISO 50001, quality ISO 9001, and occupational health and safety ISO 45001. Additionally, it is available upon request with PEFC or FSC® C011032 Chain of Custody forest certifications.