Modern-day packaging is expected to fulfil a whole host of requirements. It needs to protect products, meet growing consumer expectations in terms of sustainability, and support the circular economy – all while ensuring conformity with legal requirements, such as EU packaging regulations. At this year’s Sustainability in Packaging conference in Barcelona and the Sustainable Packaging Summit in Utrecht, Henkel will be presenting practical solutions to help companies overcome these challenges.

The EU Packaging and Packaging Waste Regulation, or PPWR for short, sets out clear requirements for the recyclability of packaging. Henkel is helping companies to meet these requirements at an early stage with practical solutions. Appearing at two flagship events – the Sustainability in Packaging conference (October 21 to 23) and the Sustainable Packaging Summit (November 10 to 12) – the adhesives and sealants specialist will be showcasing its expertise as a reliable partner for the packaging industry. “Sustainability, performance and regulatory compliance go hand in hand. Leveraging our portfolio of adhesives, coatings and testing capabilities, we offer solutions to ensure future-proof packaging design,” explains Elodie Picard, Global Head of Sustainability Packaging at Henkel.

Adhesive solutions for recycling-friendly packaging design

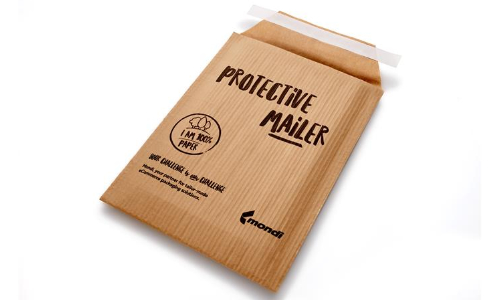

Recent products developed by Henkel Adhesive Technologies demonstrate how recyclability can be implemented in practice with a wide variety of solutions. One example is Aquence PS 3017 RE, a wash-off adhesive that won the 2024 FINAT Sustainability Award in the Optimization of Recycling category. Designed as a sustainable solution from inception, the water-based acrylic, pressure-sensitive adhesive is used for olefinic filmic labels on washable PET bottles. Besides ensuring strong adhesion, the product also delivers outstanding wash-off efficiency. The company also offers the RE range of adhesives and coatings that were specifically developed for recycling-friendly packaging design. It can be used across a broad range of applications – from packaging for cosmetic products and sterilizable food packaging to barrier packaging featuring metallized films for sensitive goods. In addition, Henkel has developed fully recyclable heat-seal coatings that are suitable for use in both primary and secondary packaging.

Real-world testing in the Henkel Packaging Recyclab

In order to ensure packaging is recyclable in practice, and not just in theory, Henkel operates its own testing centers. At the Henkel Packaging Recyclab in Düsseldorf, fiber-based packaging is tested under realistic conditions – from sample preparation and disintegration to fiber-yield evaluation. A variety of testing standards are applied, including the Cepi/4evergreen protocol and the CHI method (cyclos-HTP Institute), which evaluates different disintegration times. This enables the company to accurately assess the recyclability of packaging, while also detecting deficiencies at an early stage and making targeted improvements. An additional Recyclab was recently opened at the Inspiration Center Shanghai (ICS), further enhancing support for customers in Asia looking to increase the recyclability of their packaging.

Henkel will be on hand in Barcelona (booth 6) and Utrecht (booth 58) to showcase how products, services and partnerships are driving the transition towards a sustainable packaging industry.