More than 90 years of tradition in the manufacturing of packaging paper

Fábrica de Papel da Lapa is located in the metropolitan area of Porto, in São Paio de Oleiros, part of the Santa Maria da Feira municipality, internationally known for its emblematic August Medieval Fair, one of the country’s largest cultural events.

A family-owned company with nearly a century of history

Lapa is a family-owned business, managed by the Couto Family, which has succeeded in maintaining its warm character and essence even after more than 90 years of activity.

For the past 68 years, the company has carried out its operations at its current location, establishing itself as a benchmark in the area and as an example of generational continuity in the paper industry.

Specialists in packaging papers made from recycled fibers

The company focuses its production on packaging papers, Liner and Corrugating Grades, manufactured from 100% recycled fibers, thus contributing to sustainability and the circular economy.

These materials are essential for the packaging and corrugated board industries, sectors in which Lapa maintains a solid reputation thanks to the consistent quality of its production.

A strategic industrial and papermaking environment

Lapa is located directly across from the Corex Papeleira mill — previously known as Papeleira Portuguesa and later Papeleira Coreboard — a company that is also among Bellmer’s valued customers, reinforcing the relevance of an area with a strong papermaking tradition

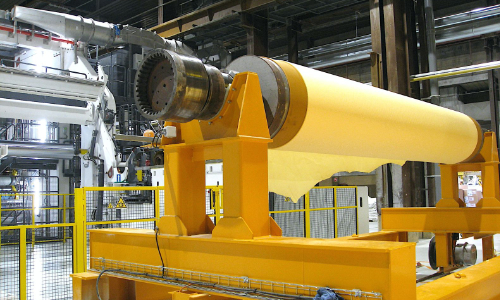

An ambitious modernization project for 2026

True to its commitment to continuous improvement, Fábrica de Papel da Lapa — led by its director Saúl Couto, with the support of his predecessor and father José Manuel — is undertaking a major upgrade of its paper machine, aimed at increasing production capacity and efficiency, while also enhancing product quality.

The project includes:

- New drying section with steel dryers, designed for operate at a maximum pressure of 10 bar

- New hood and aerothermic system

- New steam and condensate system

- New centralized oil lubrication system

Delivery and commissioning are scheduled for August 2026.

This upgrade represents a significant step forward for a company that — without losing its family essence — continues to invest in technology and innovation to ensure its competitiveness in the future.

Photo/Fábrica de Papel da Lapa