ANDRITZ has received an order from Gascogne Papier, France, to supply a PrimeLine MG (Machine Glazed) paper production line to its mill located in Mimizan, France. Start-up is scheduled for 2025.

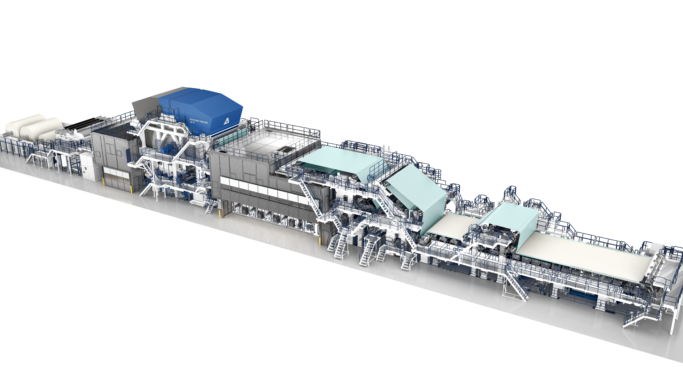

The new paper machine will have a web width of 6.8 m and a design speed of 1,300 m/min. It will thus be the widest MG paper machine worldwide producing basis weights from 120 down to 25 gsm, based on 100% softwood unbleached kraft pulp. With a capacity of 125,000 t/a it will set a new industry benchmark with the highest capacity for uncoated MG papers.

The core of the MG machine will be the world’s largest PrimeDry Steel Yankee. With a diameter of 26 ft. (7.9 m) the Yankee will enable energy-efficient drying while providing excellent surface properties such as gloss and dimensional stability. It will be manufactured and transported in pieces and assembled at the customer’s site. ANDRITZ is the first supplier worldwide delivering a Yankee of this size and the only supplier worldwide with such a unique engineering, patented manufacturing and logistics concept overcoming potentially any limits in transportation and drying performance.

The ANDRITZ MG line will replace three of the mill’s four paper machines. The main target of the investment is to establish a multi-grade production line, capable of producing more than 80 different grades of ribbed and unribbed paper.

Dominique Coutière, CEO of Gascogne Papier explains: “Investments of that scale are a big milestone for companies in our business. The selection of the right partner is a decisive success criterion. The experience and references in the MG sector as well as the customer-orientated approach of ANDRITZ convinced us. We are really looking forward to a great partnership.”

Gerald Steiner, Vice President Paper and Board at ANDRITZ, adds: “The involvement and commitment of the Gascogne team in this project and their high level of requirement regarding quality, performance, energy and environmental efficiency make this investment a unique and challenging project.”

Besides important key components in the forming section (for example adjustable table and low intensity hybrid former), the well proven ANDRITZ transfer-belt application closes the draw between press section and dryer section for highest efficiency at lowest basis weights and high-speed.

The project’s scope of supply includes the complete stock preparation line, as well as the complete PrimeLine MG paper machine, machine clothing, basic and detail engineering, overall distributed control system, motors and drives, quality control systems, web monitoring and inspection system as well as supervision, installation, and commissioning with start-up.