AFT (Aikawa Fiber Technologies) is proud to announce the successful installation and start-up of a MaxEdge150™ refiner with AFTLinx™ diagnostic service on PM5 at Essity’s Mannheim mill in Germany building on a successful previous delivery. This marks AFT’s first refining project with Essity, reinforcing a trusted partnership. The new system supports Essity’s goal of improving tissue quality at its largest mill in Europe and a key hub for hygiene brands like Zewa and Tempo.

As an integrated mill, Essity Mannheim processes primarily beech pulp, which had not previously undergone refining. The goal of the project was to improve the softness of end products, requiring a carefully tuned approach to the fiber treatment process. Beech pulp is particularly sensitive and must be handled gently, which presents a unique challenge.

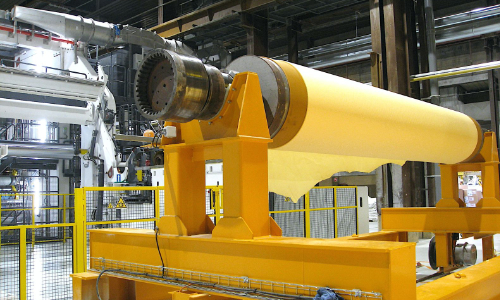

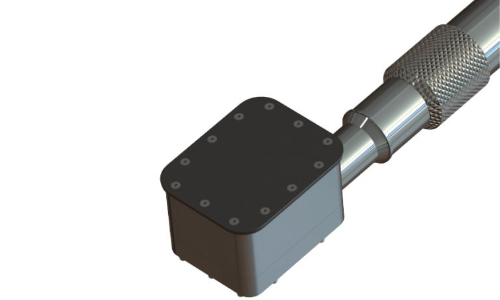

To meet this need, AFT supplied its MaxEdge150 refiner equipped with Finebar® refining plates for low intensity and energy-efficient fiber development. The installation was extended with AFTLinx™, AFT’s IoT-based diagnostic platform, to enable real-time monitoring and process optimization. AFT also provided erection, start-up, and ongoing optimization services, ensuring smooth commissioning and maximum value for the customer.

“At AFT, our focus is always on solving our customers’ process challenges and delivering real results,” said Olli-Pekka Riippa , Product Manager, AFT. “Helping Essity with their refining challenges and achieving their quality goals has been a rewarding example of this partnership in action. Our ultimate goal is a satisfied customer.”

“Introducing refining for beech pulp at our Mannheim site was a major step, and AFT proved to be a reliable and supportive partner throughout the project,” said Marco Maier, Production Manager Papermaking, Essity Mannheim. “They helped us navigate each process challenge and made the implementation easy. We’re very pleased with the results and the continuous collaboration.”

The Mannheim mill, founded in 1884, plays a leading role in Essity’s sustainability strategy, having achieved a 22% reduction in CO₂ emissions since 2005 and a 20% drop in energy consumption since 2007. The addition of AFT’s refining solution supports this ongoing commitment by improving product quality without compromising energy efficiency.

Learn more about MaxEdge: https://www.aft-global.com/en/products/maxedge-refiner