At the Functional Fiber-Based Materials & Packaging 2025 conference, Papkot® unveiled Papkot® PA, a new category of mineral-based Processing Aids that fundamentally redefines the structure, performance, and economics of papermaking and moulded fiber. This launch marks Papkot’s expansion beyond coatings, adding a second major product line to its platform.

The credibility of Papkot PA rests on rigorous industrial trials conducted with industry leader Fedrigoni at their Cordenons and Fabriano facilities. This definitive validation confirms the core promise: adding just 1% Papkot PA to the fiber mix enables up to a 20% reduction in material usage while achieving performance equivalent to traditional fiber-based containers. For a standard 280,000-tonne mill, this efficiency translates directly to the first conservative business case shared by CEO Manuel Milliery: an estimated $12.6 million in annual gross savings.

Engineered for Efficiency: Performance and Unit Economics

Papkot PA is a meticulously designed molecular solution that bypasses the limitations of traditional additives. Its proprietary plastic-free and inorganic nano-structures bond fibers at the molecular level, creating a network of rigidity and strength that delivers immediate economic value:

- Fiber Cost Reduction:A 30% stiffness increase allows manufacturers to optimize the usage of the fiber composition es reducing hard wood fibers and increase the filler contents for a 20% fiber reduction.

- Energy Consumption:Faster dewatering and reduced refining demand significantly decrease the primary energy consumption for paper making or molded fibers production lines.

- Logistics Optimization:Lighter-weight finished products—such as egg cartons that weigh 20% less—yield clear logistical gains, leading to fewer trucks and lower shipping costs.

- Performance Improvements:The launched grade delivers increased stiffness and fines retention.

Recycling the Unrecyclable: A World-First

In partnership with Fedrigoni, Papkot achieved a world-first in fiber circularity: under industrial condition, with just 1% Papkot PA, they used 100% siliconized glassine waste together with standard fibers, to make an high-performance molded fiber container.

This breakthrough transforms a high-disposal-cost material — a 350,000-tonne annual global waste stream of glassine — into a valuable raw material.

Papkot PA is validated at Technology Readiness Level 7 (TRL 7), signifying that the system prototype has been demonstrated in a real-world, operational industrial environment.

Expanding the Platform

In 2025, Papkot evolved its material science platform to address the entire fiber lifecycle with two new lines: Papkot Adhesives (plastic-free, water-based systems) and Papkot PA (mineral-based processing aids). All Papkot technologies remain plastic-free, biodegradable, fully recyclable, and food-grade.

The Competitive Edge

“We saw Papkot PA as a genuine breakthrough in material science and across the industry,” said Micaela Di Trana, VP Group Innovation & Sustainability at Fedrigoni. “It allows us to rethink fiber performance to the point where we can turn waste into high-value products. For the first time, sustainability is not a cost center but a driver of profitability. Early adopters gain a definitive advantage.”

The implications extend across the value chain: mills reduce raw materials costs, energy consumption, converters improve performance, brands meet sustainability targets—all while improving margins.

Looking Ahead: R&D for Superior Flexibility

Papkot is actively developing a new PA grade that has shown results of up to 30% increased stretch and flexibility in pilot trials with moulded fiber technology. This technology empowers sustainable, short-fiber pulps (like recycled or local materials) to achieve the mechanical performance of premium long-fiber substrates, effectively challenging leading Nordic long-fibers for almost half the raw material cost.

“I founded Papkot to eliminate plastics from packaging by radically improving fiber performance,” said Manuel Milliery, CEO & Founder. “Papkot PA delivers on that mission by entering the core of fiber processing—making paper and moulded products fundamentally stronger, lighter, and cheaper while retaining 100% original recyclability and biodegradability. With our current production capacity projected to be 20,000 tons annually, we are prioritizing partnerships with industry leaders who are committed to redefining their unit economics and environmental legacy.”

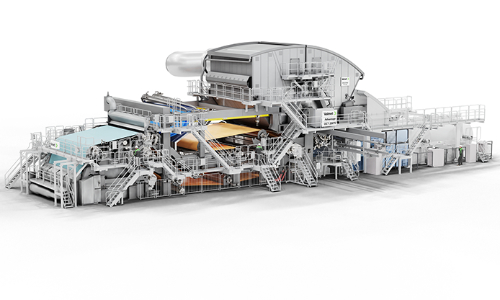

Photo/Papkot