Valmet will deliver a Quality Control System (QCS) to Metsä Tissue’s Mariestad mill in Sweden. The intelligent system will support the performance and ensure quality of the mill’s tissue machine PM 35.

“By upgrading to Valmet’s state-of-the-art QCS scanner to PM 35 we’re simplifying operations and enhancing product quality. Integrating the new system with our distributed control system and controls will reduce complexity for our operators and give us the quality control we need to improve runnability and consistency from papermaking through converting,” says Leif Forsander, Technology and Development Engineer, Metsä Tissue Scandinavia.

The order further strengthens the long-standing cooperation between Metsä Tissue and Valmet. It follows the previously announced deliveries of Valmet Advantage DCT 200 tissue making line (PM 37) and two converting lines to the same mill.

“Valmet has recently completed two successful start-ups of quality control systems at Metsä Tissue’s Nyboholm and Pauliström mills in Sweden. The cooperation has been excellent, and we are excited to continue with the next QCS project in Mariestad PM 35. By replacing the old quality control system, the customer ensures high performance and quality of the end product also in the future,” says Roger Holmedahl, Senior Sales Manager, Automation Solutions business area, Valmet.

The order is included in Valmet’s orders received of the third quarter 2025. The value of the order will not be disclosed.

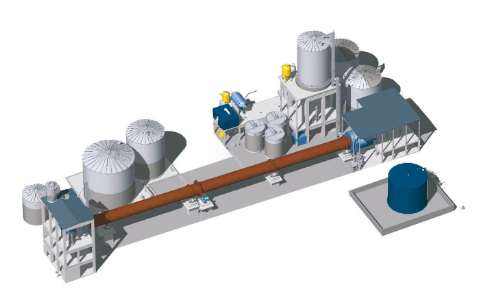

Delivery’s technical information

The delivery includes a Valmet IQ Quality Control System equipped with a scanner and basis weight, moisture and softness measurements. The system monitors and optimizes end product quality by automating essential control points. Valmet will also supply the complete mechanical installation and sheet transfer modification. A service agreement for predictive maintenance and 24/7 support ensures smooth start-up and reliable operation of the new system.