Toscotec will supply a complete rebuild of PM3’s drying section to Papeterie Le Bourray mill in Saint-Mars-la-Brière, France. This marks a repeat order for Toscotec, following the successful PM4 rebuild in 2020 where a new headbox helped the mill achieve its target.

Planned to start up by March 2026, this new pivotal project aims to support the area in achieving energy consumption reduction, marking a strong, tangible commitment to a greener future.

Energy-saving customized solution

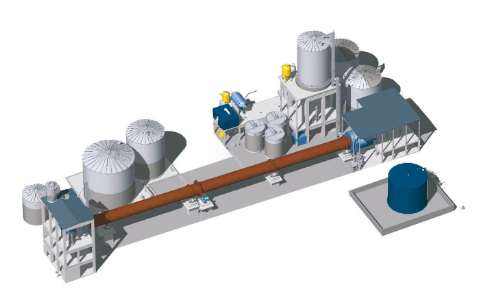

Toscotec will perform a tailor-made rebuild and an upgrade of the existing machine, which aims at significantly optimizing its efficiency and environmental performance. The scope includes upgrading the Yankee Dryer section, by featuring an innovative TT Steel Yankee Dryer 12FT with a new steam and condensate system, and a high efficiency TT Hood. Thanks to the higher drying capacity of the new Steel Yankee Dryer, it will be possible to enable the transition from the existing Mono System to a new Hybrid Gas Fired one, consisting of a wet-end hood fired by fuel and of a suction dry-end hood. The remarkable outcome of this transformation will result in a decrease in energy consumption, aligning perfectly with sustainability goals and continuing to support the consistent production capacity crucial for our customer’s success.

François Bourdin, Papeterie Le Bourray CEO, says: “This project is an important step in our efforts to save energy and reduce our environmental impact. With Toscotec’s support, we’re improving our production while moving toward a more sustainable future.”

Riccardo Gennai, Toscotec tissue division sales manager, states: “Our successful cooperation with Papeterie le Bourray continues as we equip our partners with a highly customized, turnkey drying section. We’re providing advanced technology and essential operational assistance to ensure smooth integration and set a new benchmark for eco-efficient production.”