Cleaning press felts is an essential process for producing quality paper and board. By installing a FabriClean cleaning system from IBS Paper Performance Group on a paper machine for Fluting and Testliner, the water consumption for press felt cleaning was massively reduced. Compared to the existing high-pressure shower, the FabriClean system, which operates with ultra-high pressure, requires 85% less water. At the same time, the service life of the press felt has also been increased by 25% – with consistently good dewatering properties over the entire felt lifetime.

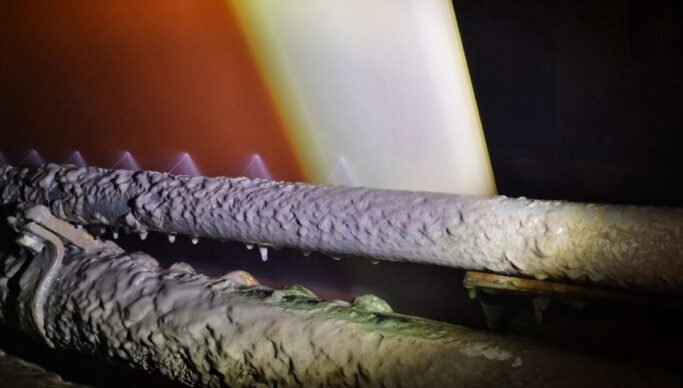

FabriClean cleaning systems provide optimal cleaning and conditioning of press felts while minimizing water consumption. The systems are set up like a typical pipe-in-pipe high- pressure shower. At considerably higher cleaning pressures, much smaller nozzles are used. Compared to conventional high-pressure showers, FabriClean systems have a significantly lower water consumption.

The results achieved in detail:

- Water consumption for press felt cleaning reduced by around 85 %.

- Service life of the press felts extended by around 25 %.

- Excellent dewatering properties of the press felts over the entire service life.

- Significantly improved machine runnability due to homogeneous felt conditioning.