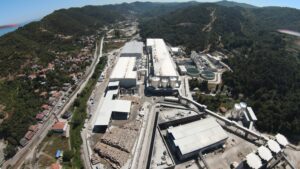

Voith, Modern Karton and Harbin Electric International Company Limited (HEI) are celebrating the successful start-up of the new high-speed XcelLine PM 6 and the associated BlueLine stock preparation plant at the Zonguldak site in Turkey. The plant will produce up to 640,000 metric tons of recycled containerboard annually, thereby increasing Modern Karton’s total production capacity to almost two million metric tons per year. This will consolidate the position of Modern Karton as one of the leading manufacturers of packaging papers in Turkey and one of the largest in Europe.

The success of this project demonstrates the long-standing and trusting cooperation between Voith and Modern Karton. The collaboration with HEI, which was commissioned by Modern Karton for project execution, was also based on partnership and trust.

“The successful start-up of our new production plant is a significant milestone for Modern Karton,” says Hamdullah Eren, Chairman of Eren Holding. “The excellent cooperation with Voith has once again shown that together we are able to achieve outstanding results. This plant will significantly expand our production capacities and strengthen our position as a market leader.”

Ralf Sorg, President Projects at Voith Paper, adds: “We are proud that Modern Karton relies on our most efficient technologies. The successful start-up of the PM 6 is proof of the performance and reliability of our solutions. Our well-thought-out and customized concept enables high-performance and sustainable paper production. This puts Modern Karton in an excellent position for the future.”

“It was a great experience to fulfill this major milestone project with Voith and HEI,” says Tamer Zengin, Project Manager of PM 6 at Modern Karton. “Voith proved to be a reliable partner with a consistent focus on project success and customer satisfaction, even in challenging times.”

Christian Deide, project manager at Voith Paper, adds: “I am pleased and grateful for the excellent cooperation with our colleagues at Modern Karton and HEI. Thanks to our open and trusting exchange right from the start, we were able to overcome all challenges up to this point and successfully start up the machine.”

Xu Tie, Project Manager at HEI, adds: “For us, it was the first processing project in the paper industry, and we are proud of this achievement in collaboration with Voith and Modern Karton. We couldn’t have asked for better partners for this endeavor.”

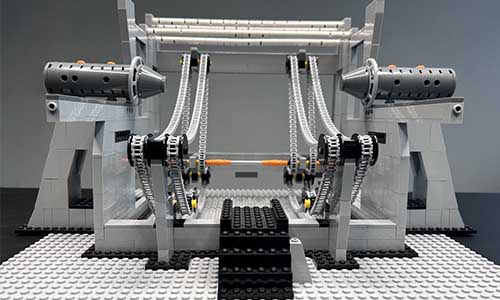

The scope of supply for the PM 6 includes Voith’s broad full-line portfolio, including the BlueLine stock preparation system with approach flow system, the XcelLine paper machine, a VariFlex Performance winder with SmoothRun vibration damping and TwinDrive double unwinding. Voith’s subsidiary Meri supplied a complete reject and sludge handling system.

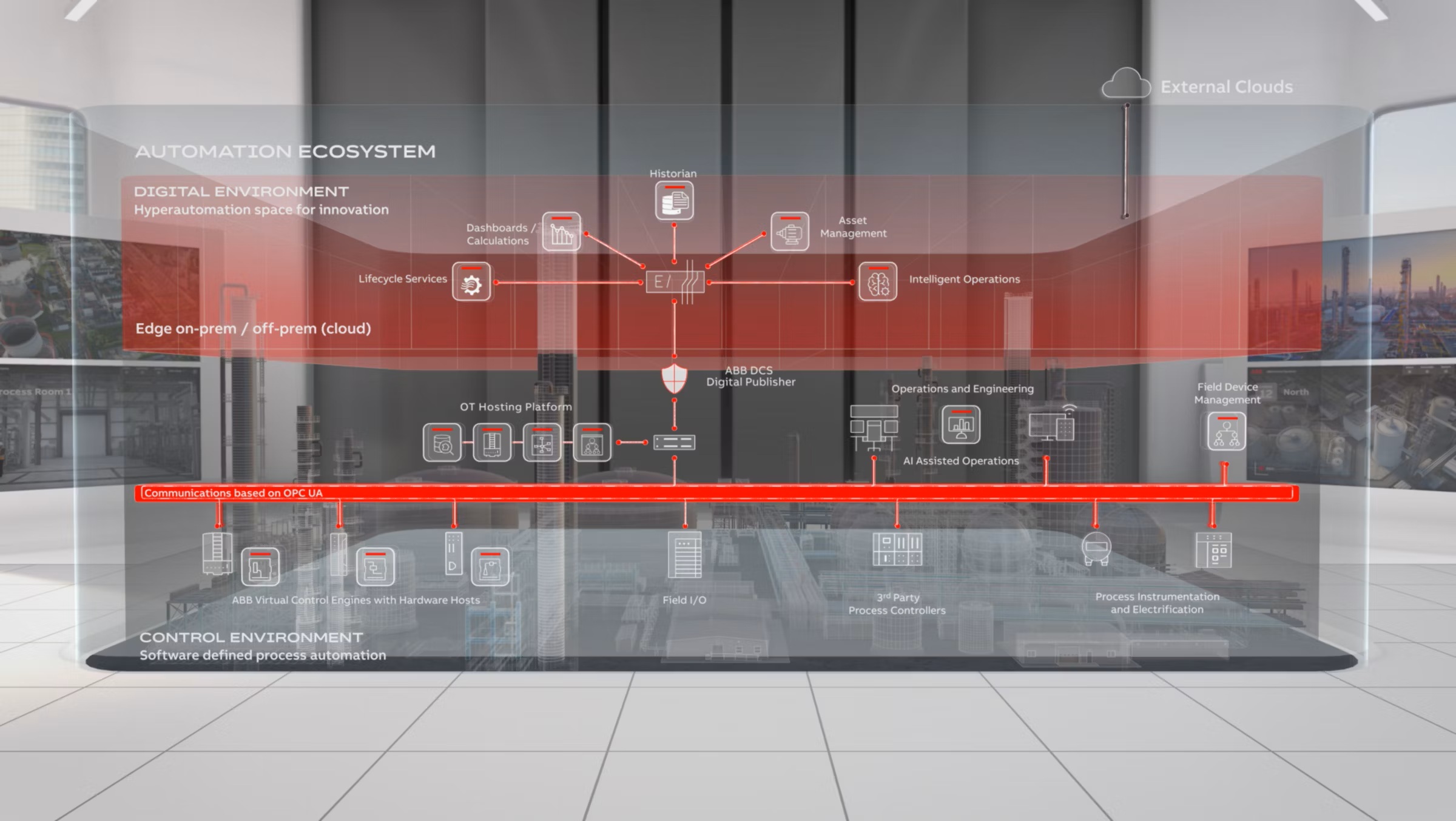

Comprehensive automation solutions such as the OnQuality quality control system, the OnCare.Health condition monitoring system, and OnControl MCS and DCS are also part of the new equipment for PM 6. Complete Papermaking 4.0 solutions, including the IIoT platform OnCumulus, the digital process control OnEfficiency.Strength and the maintenance management tool OnCare.Asset round out the scope of supply and provide Modern Karton with state-of-the-art digital technologies for maximum production efficiency.

In addition, new e-learning and virtual reality training programs from the Voith PaperSchool will be used to provide targeted training and further education for Modern Karton’s specialist staff.