Board manufacturer WEIG is relying on Voith‘s technology expertise to upgrade its BM 6 at the Mayen mill in Germany to stabilize production quality. Voith is not only supplying an intelligent quality control system (QCS) consisting of scanners, actuators and controls but will also ensure seamless integration into a PCS7 environment.

“The in-depth know-how of the Voith experts, the modular structure of the solution and the very good references in already installed systems were factors in our choice of Voith’s QCS,” says Bernd Stibi, Managing Director of WEIG Technical Liner. “In the future, we want to go even further with Voith in the development of system digitalization. Voith’s leading digital expertise and broad product and service portfolio were critical factors for us.”

The BM 6 is undergoing a decisive modernization by Voith in order to increase production efficiency. The project includes the supply, installation and commissioning of a customized solutions package. The main requirements include increasing dry content, improving moisture profiles, delivering faster grade changes and ensuring long-term service, spare and wear parts.

“We are proud to support WEIG in this pioneering project. Our QCS solutions set new standards in the industry and offer clear added value in terms of quality, efficiency and total cost of ownership,” says Ernst Jäger, Regional Sales Manager at Voith Paper.

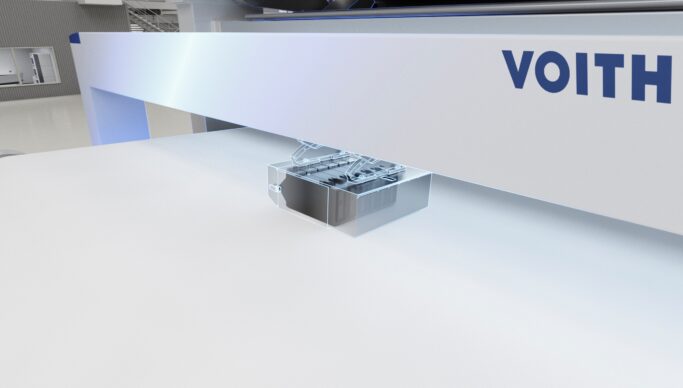

The core elements of the solution for WEIG are the measuring frames made entirely of stainless steel and the ModuleSteam steam blow box in the wire section with intelligent Profilmatic cross-profile control to increase the dry content and improve moisture profiles.

Thanks to the option of a fully virtualized system and seamless integration into common process control systems, Mayen does not require any additional interfaces. This means that all the benefits can be used by the operator at one control station. This enables efficient work, saves time and simplifies the operator’s tasks.

The use of the latest sensors, which significantly reduce the risk in terms of spare parts availability and their life cycle, enables the highest quality and reliability of the solution. The control of the ModuleSteam steam blow box via the EPI valve terminal in combination with the Profilmatic control software enables precise moisture cross-profiling as well as intelligent diagnostics, optimization functions and alarms. A tailor-made service contract based on close customer proximity rounds off the package to ensure maximum efficiency of the system over the long term.