Valmet will supply two Valmet Advantage DCT tissue lines, including automation system and three tissue rewinders, to Zhejiang Jingxing Paper Joint Stock Co., Ltd. in China. The new line will support the company’s increasing demand for high-quality tissue products in the domestic and international markets. The start-ups are planned for the first half of 2022.

The order was included in Valmet’s orders received of the first quarter 2021. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 20-30 million.

“We continuously strive for technological development to make sure we always operate at optimum production level. Through Valmet’s advanced technology, high-quality service, and joint efforts from both parties we will be able to achieve the expected goals,” says Liao Changlv, Chief Engineer, Zhejiang Jingxing Paper.

“We are very proud to be trusted as the supplier for this important project. It is always a pleasure to collaborate with customers who value state-of-the-art technology and we are convinced that this will be an excellent project,” says Fan Ze, Vice President, Sales, China, Valmet.

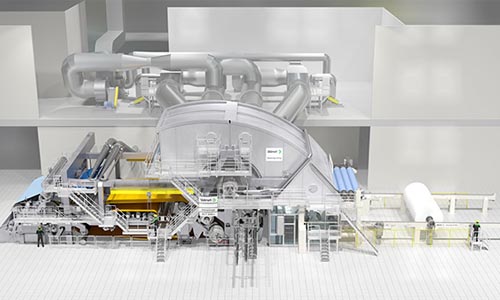

The two new tissue machines TM5 and TM6 will have a width of 5.6 m and a design speed of 2,000 m/min. The raw material to be used in the tissue production will be virgin fiber. The new production line is optimized to save energy and to enhance the quality of the final product.

Valmet’s scope of delivery will comprise complete tissue production lines featuring two Valmet Advantage DCT 200 HS tissue machines. The machines will be equipped with OptiFlo headbox and steel Yankee cylinders. It will also be featured with the Advantage tissue technology including ViscoNip press, Advantage AirCap systems, WetDust dust systems, sheet transfer systems and SoftReel P reels. The delivery includes three Valmet Focus Rewinders.

Furthermore, the delivery will include an extensive Valmet automation package with Valmet DNA machine controls, process controls and Valmet IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The new lines will add 120,000 tons of tissue to the customer’s current production.