How did the collaboration between Maflex and Rockwell Automation develop?

Francesco Petrucci, Purchasing Supervisor

The collaboration between Maflex and Rockwell Automation began with a careful evaluation of our technological and operational needs for the American market. We were looking for a partner capable of offering advanced industrial automation solutions with certified standards for this geographic area. It was essential for us to rely on a supplier with a consultative and collaborative approach.

Rockwell Automation, a global leader in industrial automation and a key player in the U.S. market, was initially chosen for specific projects. However, after the first developments and several technical meetings, we decided to adopt their platform as the standard across all our production lines.

This partnership has proven to be strategic for the continuous improvement of our technologies, providing our customers worldwide with reliable, high-quality, and widely adopted solutions. Rockwell Automation offers a broad range of products and solutions to optimize production and enhance efficiency.

Today, the AB (Allen-Bradley®) acronym appears on many components of Maflex technologies — a true mark of quality and a source of pride.

What are the tangible benefits of this collaboration for Maflex and its customers?

Marco Lorenzetti, Software Engineering Supervisor

The partnership with Rockwell Automation has transformed the way we build our machines, enabling us to integrate advanced technologies ranging from motors to key electrical panel components. This integration has significantly improved the efficiency and precision of our production lines. As a result, we’ve seen a substantial reduction in downtime and better control over performance.

Our goal is to respond faster and more effectively to our customers’ needs. For them, this translates into higher-quality products manufactured with lower operating costs. The adoption of Rockwell Automation solutions has made a real, measurable difference in the performance of our technology — a benefit that our customers experience directly in their daily operations.

What Rockwell Automation technologies are integrated into your machines, and how do they enhance production efficiency?

Marco Lorenzetti, Software Engineering Supervisor

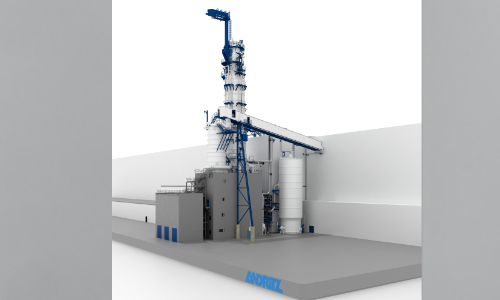

We integrate a wide range of Rockwell Automation technologies into our machines, including their advanced control systems, electromechanics, and motors. These sophisticated components are essential for automating and optimizing processes.

Electric drives, for example, improve control and speed regulation of the machines, while circuit breakers and residual current devices enhance operational safety. Safety controllers are key to embedding safety functions into our production lines, ensuring operations are not only efficient but also fully compliant with the highest safety standards.

All of this allows our machines to operate with outstanding precision and minimal manual intervention, significantly boosting our overall production efficiency. This level of technological integration results in highly reliable and high-performance solutions, ensuring that converters receive consistent quality over time.

How is industrial automation changing the way tissue converting machines are designed and built?

Luca Mazzotti, General Manager

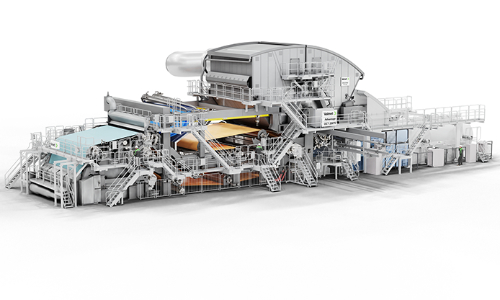

Industrial automation is revolutionizing the industry and allowing us to design tissue converting machines that are increasingly efficient, flexible, and capable of adapting quickly to new production and safety standards.

The goal is not only to meet the growing demands for efficiency and cost reduction, but also to provide greater versatility to address the unique characteristics of global markets.

Year after year, mechanics are giving way to electronics, which now play a central role in controlling operational dynamics. This shift not only improves performance but also allows for more precise and responsive management of the entire production process.

Staying competitive in a rapidly evolving sector means investing in smart, scalable solutions that can adapt to the specific needs of different regions and meet the demands of an increasingly diverse market.

What are the company’s main goals for the future in the tissue converting industry?

Luca Mazzotti, General Manager

Our future goals are clear and ambitious: further expand our production, continue to innovate, and strengthen our global presence.

We are committed to developing increasingly diverse technologies that enhance the productivity and efficiency of our modular machines and converting lines, to precisely meet our customers’ production requirements.

Meeting their specific needs and the characteristics of the finished product they aim to convert is what guides every one of our projects.

To achieve these goals, we work daily to reinforce our ability to deliver a complete service — from concept to final implementation — ensuring that every system is perfectly aligned with customer operations and maintains peak efficiency over time.

Using high-quality components and working with top-level partners is essential to fulfilling this vision.