Paper” and “stretch” are words that don’t usually go together. But in a reality where regulations on single-use plastics are increasing, paper is proving itself a worthy player as an alternative to plastic-containing products.

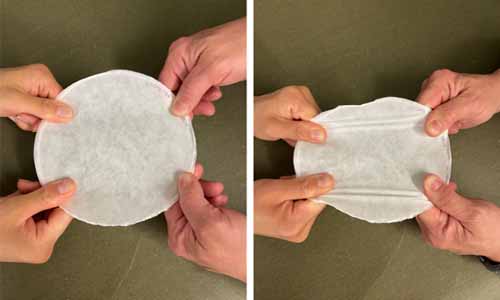

To help the pulp and paper sector enter the market of stretchable packaging and diversify their products, FPInnovations has developed a paper-mill-friendly approach for stretchable paper that can reach up to 20% stretch. To put that number into perspective, paper hasn’t been able to cross the 10% stretch threshold – up until now.

What’s changed?

The increase in regulations and bans around single-use plastics is leading to a growing demand for non-plastic alternatives, and new doors are opening for the market of sustainable paper packaging.

“In the past, the limitation of paper had to do with the extent of its stretch and extensibility”, says Rafik Allem, Senior Researcher at FPInnovations. “At 10% stretch, paper wasn’t able to compete with the stretchable performance of plastics”.

Increasing paper stretch, among other criteria, allows traditional printing and writing paper producers to enter new market segments such as flexible packaging (ex. wrappers, pouches, and overwraps) that are currently dominated by plastic-containing products. This also opens the door for more sustainable options for companies and consumers.

FPInnovations’ unique recipe

Over the past few years, FPInnovations has been developing new solutions to help newsprint producers diversify their products and to create new markets for cellulose-based products. One of these solutions is stretchable paper.

The new patented stretchable paper technology developed by FPInnovations meets end-use requirements for potential new product lines with stretch that is above traditional specifications. As the name suggests, the main criterion is stretchability. But that’s not all.

The newly-developed stretchable paper is made up mainly of wood fibres, and depending on mill setups, its production may not require significant capital investments. Indeed, the addition of an extensible polymer is one of the requirements for stretchability increase. FPInnovations is working to improve this new product to go beyond 20% stretch using biopolymers to allow the final product to biodegrade.

FPInnovations has conducted several pilot trials of the stretchable paper solution and is ready to work with partners to produce it at paper mills. The unique composition of stretchable paper ensures a great quality that is comparable to higher-end and pricier products currently on the market.

Endless possibilities

The future of flexible sustainable paper packaging looks bright. The packaging expertise that FPInnovations has developed will help paper mills improve their existing products and diversify their portfolio to displace single-use plastics.

For more information on this exciting project, contact Rafik Allem, Senior Researcher at FPInnovations, or Stéphan Larivière, Pulp & Paper Industry Sector Leader.