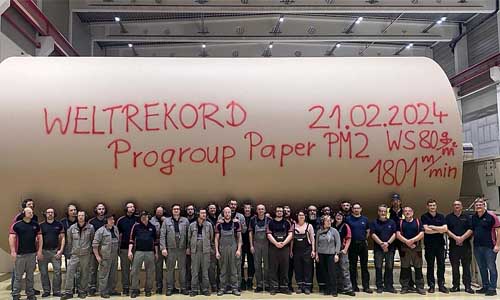

11 April 2024 – 1,801 metres per minute – this was the breathtaking speed at which Progroup’s PM2 paper machine in Eisenhüttenstadt produced the paper WS 80g for a period of 25 hours. This paper had never been produced at such a fast speed before and so it represents a new world record, as the manufacturer of the paper machine has since confirmed.

Detlef Weidlich, Progroup’s site manager in Eisenhüttenstadt, explains how this amazing record came about on 21 February: “We used a sophisticated experimental plan as the basis for defining the approach we would use in the speed test. The result was that we produced WS 80g paper over a period of 25 hours – and we did so at a speed of 1,801 metres per minute, so more than 108 kilometres per hour! This was an outstanding effort by the whole team. I’d like to thank all my colleagues, who should be very proud of this achievement!”

“It’s just like in sport”

Detlef Weidlich goes on to explain: “It’s just like in sport: A key factor is thorough preparation and planning. We started thinking about when would be a suitable time to do this back at the end of November. We devised a plan for how the machine should be set up and run, what risks, such as power spikes, need to be considered, and we also gave some preliminary thought to the technology involved. We achieved the required level of stability in December 2023 and January 2024.”

And just like good football coaches, Weidlich and his team also assembled and prepared the team to carry out the speed test. As February progressed, the day in question drew ever closer: “Following a shutdown and the clothing change on 1 February, then starting the machine again, we were up to full speed by the third week of the month. After this, we just needed to check whether all the technical and organisational requirements were in place – and then simply do it!” As you can see, the team from Eisenhüttenstadt accomplished this with great success!

Progroup innovations continue to set standards in the industry

The 300-metre-long paper machine, which was optimised for producing light “Next fibre® papers”, has a working width of 10.20 metres and is still regarded in the industry today as a milestone for the production of containerboard. In Eisenhüttenstadt, either four paper reels, each measuring 2.50 metres, or three paper reels, each measuring 3.35 metres, are produced simultaneously around the clock. The performance features and specifications are the same as those of machines used in the graphic design sector. It is operated with four times as many control loops and circuits as an Airbus A380, for example.

Next fibre® containerboard is very light and sustainable

The machine in Eisenhüttenstadt produces super-lightweight papers with a grammage of from 58 to 90 grams based on recovered paper. Despite using fewer raw materials and fibres, the containerboard sold under the next fibre® brand boasts the same strength values as traditional, heavy grades. The manufacture of next fibre® papers alone already saves an average of around 50 per cent of CO2 compared to conventional papers. But the potential to make savings also continues throughout the life cycle. The finished next board® corrugated board sheets and the packaging that is made from them are light and thin-walled and when transported can save up to 24 per cent of CO2 – compared to heavy grades.