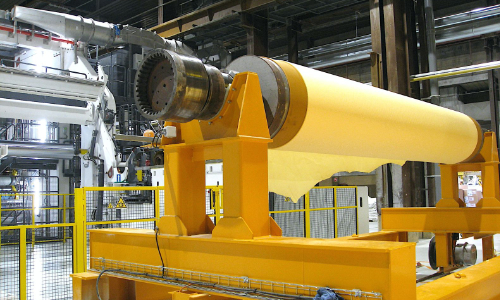

Papelera Reyes, a leading tissue producer in the South American market, is the first company worldwide to integrate the groundbreaking Valmet Warm-up Next process into its production line. The installation of this technology at the Papel Paracas site, located in Callao, Peru, marks a new chapter in the long-standing collaboration between Papelera Reyes and Valmet Tissue Converting. The harsh desert environment provides a powerful demonstration of the robustness and efficiency of Valmet’s solution, designed to deliver peak performance even under the most challenging conditions. Already operating four cutting-edge Constellation® lines by Valmet, Papelera Reyes once again confirms its commitment to highly efficient systems and reaffirms its role as a forward-looking leader in the tissue industry.

“With the installation of the Valmet Warm-up Next process, we take a natural step forward in the shared journey of innovation and growth we have built with Valmet,” states Sebastian Reyes, Operations Manager, of Papelera Reyes that concludes “This next-generation hot embossing solution sets a new benchmark in the industry, allowing us to ensure consistently high product standards while adapting swiftly and effectively to the demands of a rapidly changing market. This achievement underscores our long-term commitment to innovation, performance, and uncompromising quality across all our operations.”

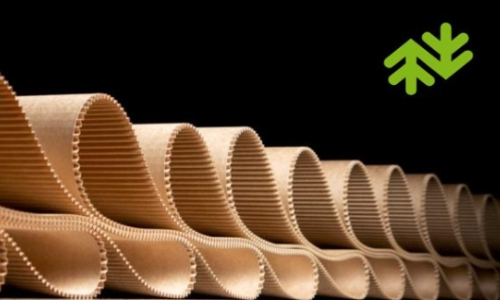

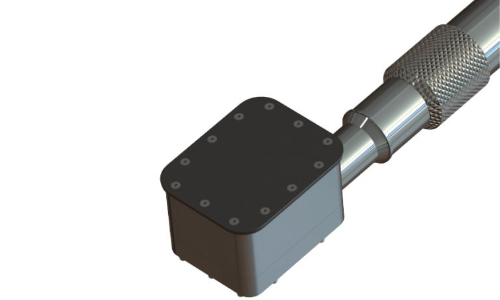

Warm-up Next process takes embossing to the next level, delivering up to 50% more caliper, increased softness, reduced paper consumption, up to 60% energy savings, and improved operational safety while maintaining softness, absorbency, and tensile strength, all without using water. Warm-up Next process enables manufacturers to achieve outstanding performance and maintain a competitive edge in an increasingly demanding market.

The Warm-up Next process expands benefits of Warm-up Contactless by introducing pre-embossing capabilities for outstanding results on finished products, offering endless possibilities for product configuration, both for hygienic and kitchen towel products, with pre-embossing micro, as an example. Furthermore, this technology seamlessly integrates a single or double rubber-to-steel pre-embossing station into existing embossing units, without significant layout changes to tissue converting production lines in the case of a single rubber-to-steel pre-embossing station. The Warm-up Next process eliminates the need for a water source, removing the tissue wetting and drying steps during production. Additionally, this process ensures that the complexity of the production line remains unchanged.

Outstanding embossing results can be achieved with the Valmet Warm-up Next process, even in desert conditions, without using a single drop of water and without compromising end-product quality.