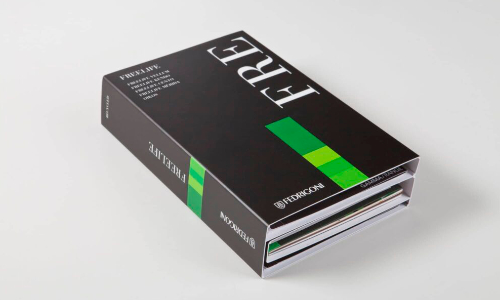

Mondi, a global leader in sustainable packaging and paper, has expanded its portfolio with a high-performance digital printing solution, enabling customised, high-volume packaging following the acquisition of Schumacher Packaging’s Western European operations. KOMSA, a leading distributor for digital infrastructure in Germany, has been using this option to print consecutive barcodes directly onto corrugated board packaging, without additional labels or manual labelling.

KOMSA dispatches up to 35,000 parcels daily, making efficiency critical to maintaining next-day delivery. One key improvement has been the integration of consecutive barcodes directly onto the packaging using Mondi’s high-performance digital printing solution.

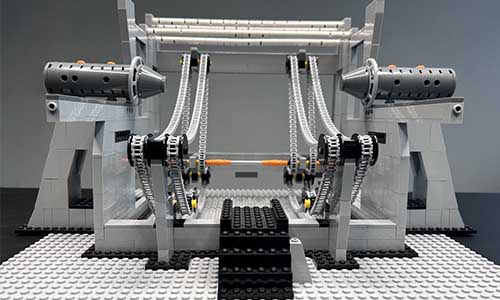

Across KOMSA’s packaging line, 60 scanners identify and allocate each parcel. Previously, barcodes were applied using label dispensers. Now, they are printed directly onto the packaging – precisely positioned and visible on all four sides. This approach reduces lead times, lowers costs and minimises the risk of errors.

“The collaboration with Mondi is a real benefit for us – technologically, economically and strategically”, summarises Harald Josef Ollinger, Vice President Marketing & Communications at KOMSA. “We are not only making our logistics processes more efficient, but also more sustainable.”

Mondi’s high-performance digital printing enables customised barcodes and complex print images in high-resolution without the need for printing plates or clichés. The process uses water-based, food-compliant inks, and offers maximum flexibility. Series, seasonal campaigns, regional designs and individualised QR codes can be produced in a single production run with short lead times and faster time-to-market.