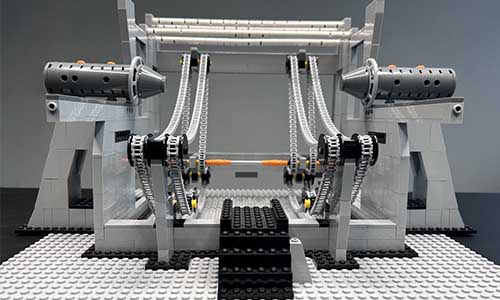

Green Bay Packaging has significantly improved operational reliability and detrashing throughput at its Green Bay, WI facility through the implementation of Voith’s OnControl.Pulping Detrashing solution.

Installed and running consistently since March 4, 2024, the smart control system has automated key parts of the detrashing process and enabled more steady-state operations. The system has reduced process variability typically associated with standard timed-purges – resulting in greater process stability and consistency. Cleaner rejects and less equipment plugging were also observed benefits.

Voith’s OnControl.Pulping Detrashing dynamically adjusts the detrashing process based on real-time data. This optimization improves fiber recovery, reduces contaminants in the accepts and enhances operational reliability. The system automates cycle timing and adapts to varying raw material conditions, ensuring consistent performance and process stability across shifts. The implementation has also enabled Green Bay Packaging to optimize mixed paper utilization while maintaining the high quality expected by their customers.

Voith’s OnControl.Pulping Detrashing dynamically adjusts the detrashing process based on real-time data. This optimization improves fiber recovery, reduces contaminants in the accepts and enhances operational reliability. The system automates cycle timing and adapts to varying raw material conditions, ensuring consistent performance and process stability across shifts. The implementation has also enabled Green Bay Packaging to optimize mixed paper utilization while maintaining the high quality expected by their customers.

“Our goal was to maximize our pulping efficiency,” said William Cone, Vice President of Mill Operations at Green Bay Packaging. “OnControl.Pulping Detrashing has helped us achieve that by delivering reduced variability and freeing up our team to focus on higher-value tasks. We could not see operating without it anymore.”

OnControl.Pulping Detrashing can be implemented as a stand-alone solution or integrated into Voith’s MillOne digital ecosystem. By connecting to other modules, the information collected can be placed in a broader context and linked to additional plant data. This lays the foundation for further automation in stock preparation and supports the development toward autonomous paper mills.