As part of a DA Tower installation, deugro, in close cooperation with dteq Transport Engineering Solutions (dteq), successfully delivered critical oversized components to the construction site at the Punta Pereira private terminal in Uruguay.

The cargo included a 10.91 x 10.35 x 10.17-meter and 56-metric-ton unit, an impressive 34.66 x 9.35 x 9.13-meter and 140-metric-ton unit, and a 150-metric-ton unit with a volume of 18.84 x 9.25 x 9.14 meters. All components were shipped by heavy lift vessel from the Port of Taicang, China to the Punta Pereira private terminal in Uruguay.

Although it was “only” two kilometers long, the biggest challenge was the on-carriage after vessel discharge from the port to the laydown area. This encompassed a variety of tight turns, buildings extremely close to the road, and street furniture along the route—limiting the cargo’s ability to transit to a minimum. To ensure a safe and efficient transport against the backdrop of these restrictions, as well as the delivery of all components on time and according to budget, meticulous preparation and planning to the centimeter were required right from the start.

deugro therefore commissioned the engineers at dteq to conduct a road survey, with the aim to determine the dimensional limits and corresponding maximum technically feasible cargo dimensions and transport envelops that could be safely and efficiently moved across the infrastructure—from the port to the laydown area. This way, it was possible to ensure from the outset that the client’s cargo could be successfully delivered without modifications to the cargo itself and without extensive transport management measures along the route, reducing time and costs.

“One of the challenging aspects of the project was the need to transport the cargo units through confined areas in the project site. dteq worked very closely with deugro Uruguay to gather all the information needed to develop transport solutions and swept path analyses needed in order to ensure a safe transport to the final place of rest on site. This allowed us to work on horizontal and vertical swept path simulations, in which we were able to identify potential clashes with existing buildings and road furniture ahead of the transport so that they could be removed prior to execution. Ultimately, all transports went smoothly and were moved with a minimum clearance of 100 millimeters,” said Irene Gonzalez, Transport Engineer at dteq Transport Engineering Solutions.

Thanks to the precise calculations and analyses, the impressive cargo components were safely moved to the laydown area at the construction site—despite several buildings located extremely close to the transport route, various sharp turns, and further bottlenecks—through centimeter-accurate maneuvering and without any modifications to the cargo or the buildings, and without major transport management measures along the route, apart from the removal of a few lamp posts and letters.

“This allowed the oversized cargo units to be transported at their maximum dimensions, significantly reducing subsequent assembly costs, while avoiding having to choose between modifying or downsizing the cargo units and removing buildings along the transport corridor—resulting in further substantial cost savings,” said Nicolas Gomez, Country Manager, deugro Uruguay.

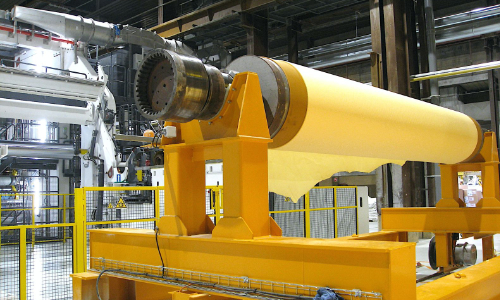

Another challenge was the width and length of the oversized unit, measuring 34.66 x 9.35 x 9.13 meters. For transportation in accordance with the required safety and industry standards, side-by-side axle lines were required. However, such equipment is scarcely available within Uruguay, and mobilizing axle lines from abroad would have significantly increased costs. To address this, the truck was substituted with a Self-Propelled Modular Transporter (SPMT), allowing the out-of-gauge cargo components to be loaded onto shorter equipment. To guide the cargo units from the vessel to the construction site—along all critical intersections and bottlenecks—deugro’s project managers were on-site to personally coordinate and supervise all operations.

“The close and excellent collaboration with the client, dteq and all partners involved, along with the precise project preparation and execution, ensured that all cargo components were delivered safely and on time,” said Nicolas Gomez, Country Manager, deugro Uruguay.