While many countries in the world are getting lockdown through Covid-19 lockdown, BTG has managed to realize several start-ups of its Yankee Performance Monitoring system (called VigilancePRO), allowing customers to keep their implementation plans on track, ensuring business continuity.

For two systems in Sweden and one in France, configuration has been realized remotely by BTG specialists. In addition, exploiting the remote access capabilities built into VigilancePRO, an operators training seminar took place, repeated on subsequent days to cover different shifts at the site.

Designed to be a networked system or part of a multi-site enterprise solution, VigilancePRO naturally enables off-site connectivity.

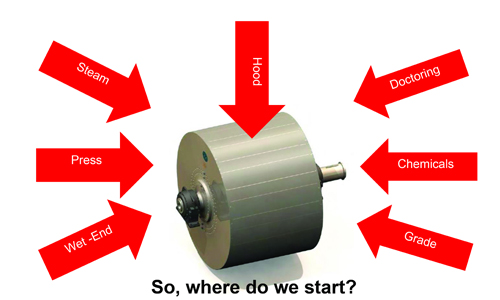

VigilancePRO uses an advanced data historian and custom graphics to collect and display critical crepe blade vibration data, with several unique real-time data features. In addition, VigilancePRO can collect multiple performance tags from Yankee chemical and steam and condensate systems as well as scanning the unique bar code on a BTG high performance crepe blade label. Operators and engineers thus have a rich environment with which to troubleshoot and enhance Yankee operating performance.

BTG Group has launched VigilancePRO in 2019 by BTG and is now installed in about 20 mills globally.

BTG Group is a multinational provider of integrated, highly specialized process solutions for the global pulp and paper industry. BTG is committed to help its customers achieve significant, sustainable gains in business performance.