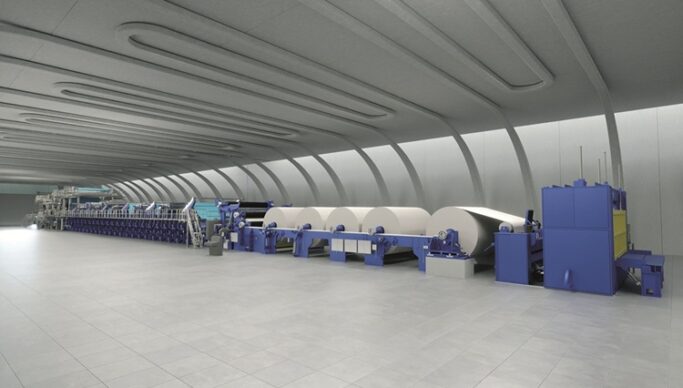

Efficient, sustainable, and tailor-made: At this year’s Zellcheming Expo in Wiesbaden, Bellmer showcases cutting-edge system solutions for the paper industry.

From July 01–03 2025 Bellmer will present its extensive portfolio for paper production at booth 148 in Hall North of the RheinMain CongressCenter – with a special focus on intelligent, energy-efficient end-to-end solutions for the entire production process.

Comprehensive Solutions for Modern Paper Mills

Bellmer offers fully integrated production lines – from stock preparation and headbox to reel-up – all from a single source. The proven Bellmer TurboLine allows for customized modernization of production facilities and provides a wide range of options for improving quality and efficiency.

Bellmer’s stock preparation stands for highly efficient fiber processing – from bale handling to pulp treatment using refiners and detrashers, all the way to reject handling systems. In the approach flow system, Bellmer also impresses with minimal energy and water consumption while consistently achieving high end-product quality – a significant contribution to reducing raw material costs.

On Wednesday, July 2, 2025, David Dostal will present a best-practice talk, offering practical insights into successful strategies for reducing OPEX costs in OCC lines. The focus will be on the latest innovations aimed at maximizing yield and reducing energy consumption.

A key highlight: the TurboJetter headbox, which has proven its performance in numerous installations. This is complemented by advanced dewatering components and the innovative TurboShaker breast roll shaking system, which improves formation and paper properties through high-frequency shaking with low energy consumption.

Energy-Efficient Components and Strong Partnerships

Energy efficiency is a top priority in today’s paper production. Experts in shoe presses and calenders, along with specialists from Bellmer’s Air & Steam Systems division, will be present at the booth to share solutions for reducing energy consumption sustainably.

Bellmer also showcases the TurboReeler, a high-performance reel that marks the reliable end of a successful production line. Its new center drive enables fully automated roll transport – even with diameters up to 4,200 mm. The TurboWinder ensures precision slitting, tailored to each customer’s requirements, and produces top-quality paper grades through the perfect interplay of drive parameters and rolls.

Coating Technology Innovations: Focus on Curtain Coating

Coating Technology Innovations: Focus on Curtain Coating

Coating remains a strong focus for Bellmer. Together with its Swiss partner TSE Troller, the company presents the latest innovations in curtain coating. The centerpiece is the TurboCurtainCoater, an easy-to-use system that delivers premium coating or pre-coating quality directly on the paper machine.

At the core is a multi-layer cascade nozzle, using a pre-metered curtain coating method. The paper web passes under a falling curtain of liquid, ensuring precise and uniform application. This technique not only improves cost-efficiency but also increases productivity through the simultaneous application of multiple layers – enabling the creation of innovative new paper products.

Sustainable Water and Sludge Treatment Solutions

Bellmer also addresses modern separation technology for sustainable mechanical treatment of water and wastewater streams. Together with the Bellmer Kufferath team, experts will provide insights into advanced solutions in this area.

Bellmer – Innovation Since 1842

Bellmer has been a driver of innovation in paper machinery manufacturing since 1842. This family-owned company employs over 800 people worldwide and is a trusted partner for tailored, precise, and sustainable solutions across all aspects of paper production.

For more information, visit:

🔗 www.bellmer.com