The new MasterDry DM product line from international technology group ANDRITZ improves evaporation, contamination resistance, and lifetime in dryer fabrics. The single-layer design thus offers important advantages over the double and one-and-a-half-layer dryer fabrics made of standard polyester mainly found on the European market.

New technical materials

MD and CMD (machine-direction, cross-machine direction) yarns are made of hydrolysis-resistant PET polymer. Thus, they can be applied to positions with higher temperatures. The properties and processing of the machine direction-(MD) yarn is such that the fabric has up to 35% higher wear potential than comparable fabrics from other manufacturers.

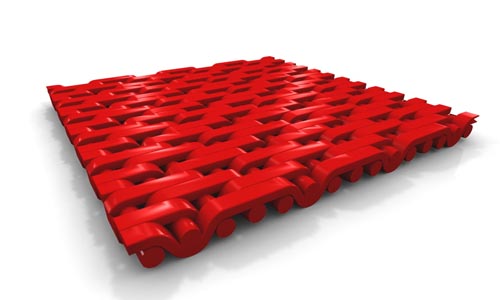

Fabric structure with many strengths

The single-layer MasterDry DM dryer fabrics have excellent running properties due to best bending stiffness and lowest skew. Another advantage of the special single-layer fabrics is their much higher contamination resistance than comparable products. The structure has no hidden pockets within the fabric where dirt could accumulate. This makes the fabrics easy to clean. The fabrics in the MasterDry DM product line also have a very large contact surface area with the paper, which ensures first-class heat transfer from the rolls. Depending on the design, the contact area can be up to 50%, with permeability levels from 100 to 300 cfm.

Quality – Made in Europe

MasterDry DM fabrics are manufactured exclusively at ANDRITZ production sites in Germany and Austria. This enables ANDRITZ to guarantee short delivery times and respond flexibly to customer requirements.