Coupled with ABB Ability™ Collaborative Operations, the Advanced Process Control project will help drive efficiency gains

Double A, one of Asia’s leading pulp and paper producers, has selected ABB Ability™ Advanced Process Control (APC) for its pulp mill in Prachinburi, Thailand. The new contract includes full supply and implementation of ABB’s OPT800 Caust and OPT800 Lime APC applications for better control of the causticizing and lime production processes.

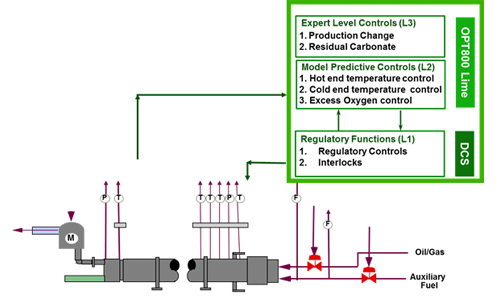

Both APC applications leverage multivariable Model Predictive Control (MPC) algorithms integrated into ABB Ability™ System 800xA distributed control system. OPT800 Caust stabilizes the white liquor quality by controlling the lime feed and green liquor, causticizing efficiency and production rate changes. OPT800 Lime optimizes kiln operations to reduce energy consumption and emissions, increase reburned lime availability and decrease residual carbonate variations.

“APC represents the future for the pulp and paper industry, with powerful applications to help reduce material costs while maintaining quality and productivity,” explained Thanom Saenchompoo, Sales Manager, ABB. “One of the main benefits of APC is the ability for operators to make changes to processes, observe their impact and keep fine tuning until they are ready to implement those changes in the actual operation.”

The installation and commissioning for the OPT800 Lime APC has just been completed while OPT800 Caust APC will take place by end of the first quarter in 2020.

Completing the order is an ABB Ability™ Collaborative Operations service agreement, which will help monitor and sustain the performance of the batch digester, lime kiln and causticizers.