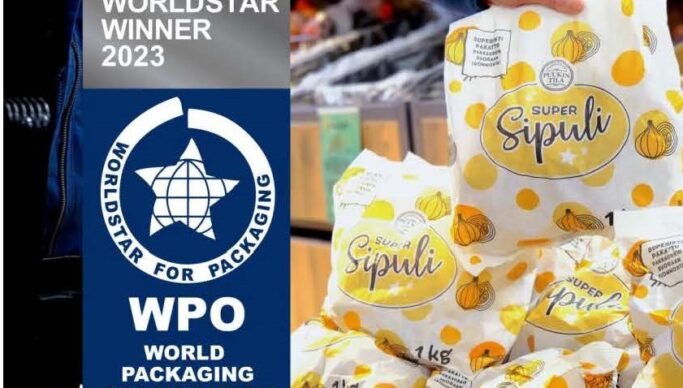

A recyclable pouch made of Paptic® to replace plastic in vegetable packaging is a WorldStar award winner. The winning wood-fiber-based packaging solution was invented when Paptic Ltd and Marvaco Ltd joined forces to respond to a call from Puukin Tila, a Finnish farm, to replace plastic in onion packaging. Paptic®, a renewable material, and Marvaco Expanded Gamut Printing with Flint Group C2C Material Health certified inks made the new, truly sustainable vegetable packaging possible. In the optimized packaging, all sustainability aspects were considered, including the substrate, design, printing, and inks.

“Our mission is to provide a recyclable and renewable alternative to plastic films in packaging, and we are constantly developing new solutions with sustainably focused companies. We are delighted of the fruitful co-operation with Puukin tila, Marvaco and Flint Group in this project and that we were awarded with a WorldStar award”, says Katja Jokiaho, Chief Sales Officer, Paptic Ltd.

Paptic® is a fibre-based substrate to replace plastics in packaging. The lightweight material is soft, with excellent puncture and tear resistance and heat sealability properties. Various products benefit from being packed in breathable materials, like Paptic®.

“We created a simple and sustainable design for onion packaging by reducing ink consumption and the number of colours used in printing”, explains Mirva Koskinen, Brand Sales Manager at Marvaco. Only three colours were used, but the colorful design was possible due to the process of printing. With Flint Group’s water-based offering, the use of heavy metals was eliminated, and the waste was minimized. The Cradle-to-Cradle Material Health certified inks used are also certified for OK compost. Despite the environmentally wiser choices, the desired colourful design was achieved.

Petri Puukki, the owner of Puukin Tila, is satisfied with the results: “We wanted to make a difference and pack our locally produced onions in a sustainable way. The material selection keeps the onions fresh for longer and the new packaging also looks fresh!”

The project was completed in just a few months.