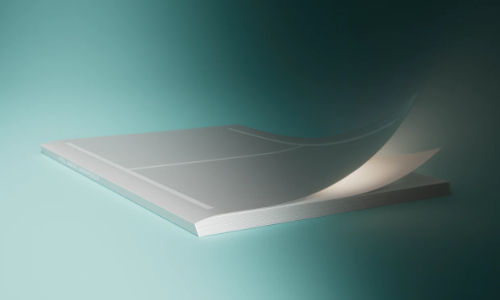

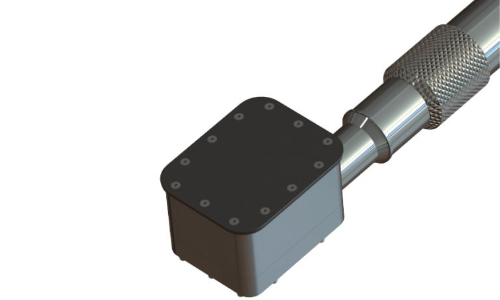

Fedrigoni Group Special Papers of NA (FSPNA) in Waterford, New York has integrated Cristini’s FiberScan microwave sensors into closed control loops on both paper machines to manage sheet consistency on the forming fabric. Installed under the forming fabric in strategic placement along the Fourdrinier , FiberScan sensors continuously measure sheet consistency in real-time. This data is then used to maintain target consistency by adjusting vacuum elements upstream of the sensor. Variations in furnish have a direct impact on drainage, therefore it is important to maintain tight consistency control for good sheet formation and other key attributes.

“Historically, our operators relied on the position of the dry-line to estimate consistency which was difficult control over all shifts and all levels of operator experience. Before the FiberScan sensors were installed many years ago, operators only had a visual target to shoot for, now they have something quantifiable”, said Dolph Beyer, VP Operations FSPNA.

Lawrence Yane, Eng., M.Sc. Yane of Cristini continued: “By using FiberScan’s data in a closed control loop, FSPNA has effectively developed an automated feedback system. The result is improved stability, faster correction of disturbances, and a more consistent, high-quality sheet.”

This is a clear example of how smart sensing and modern automation can elevate traditional papermaking, turning process complexity into an opportunity for precision and repeatability.

If you’re exploring ways to modernize sheet control or bring more real-time intelligence into your forming section, technologies like FiberScan are quickly becoming essential tools for achieving next-level performance.

Fedrigoni Special Papers NA is a producer quality papers that bring tactility and impact to print. Be it digital, offset, envelopes, packaging or even letterpress, the Mohawk product portfolio has the ability to make your next project more beautiful, effective and memorable.