Why more brands are turning to paper-based solutions – and how Sappi is shaping the shift

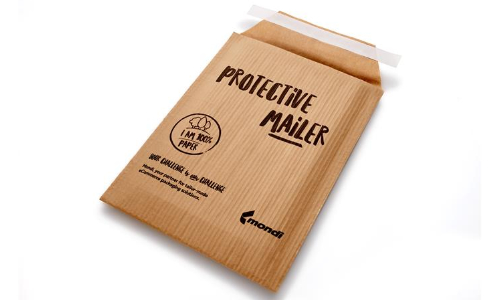

Across the packaging industry, more companies are rethinking how they protect their products while meeting rising expectations for recyclability. Regulations are tightening at national and EU level. Retailers want packaging that fits cleanly into existing recycling systems. Consumers expect materials that feel simple and responsible to dispose of. And brand owners are searching for a path that balances performance safety and cost.

For Sappi, this rising demand has not come as a surprise: the company has been developing barrier papers for more than a decade. These papers are mono-material and offer the protection needed for many products, work on existing packaging machines with manageable adjustments, and can be recycled in the paper waste stream.

“The interest has grown fast in recent years,” says Gustavo Duarte, Head of Business Development at Sappi Europe. “Brand owners want solutions that actually solve their problems, not just ideas that sound good in theory. And they want an alternative to plastic that fits into their real production environment.”

Meeting the demands of modern packaging lines

Duarte says that decisions around new packaging materials revolve around three essential requirements. The first is product protection. All products span many categories – tea, cereals, chocolate, flour, dried fruits and nuts, instant soups, sugar and more – and each has different sensitivities. Some need protection from moisture. Others need a barrier against oxygen or mineral oil.

“You can’t compromise shelf life under any circumstances,” he says. “If the barrier fails, the product is at risk and the supply chain suffers. So we test everything carefully and consistently. We measure permeation rates, check moisture resistance, and verify seal strength for grades that need heat sealing.”

The second requirement is the ability to run on existing packaging machines. Many packaging lines were originally designed for plastic films and optimised over the years, which are strong, flexible, and resistant to tearing. Paper behaves differently, even when it will reach the same performance than plastic.

“Plastic films are more flexible and forgiving in the process,” explains Alexander Schröder, Product Application Leader at Sappi. “Paper needs a different kind of care and attention. Tension, heat, and sealing pressure all play a role. But this doesn’t mean customers need new lines. Often it comes down to fine-tuning. We are working close with machine manufacturers to help customers see what needs to be adjusted before they switch.”

Schröder says that most customers manage the adaptation on their own. “Technicians know their machines well. They understand where small changes can make a big difference. We support them when needed, but many manage the transition quickly.”

The third requirement is recyclability. This is one of the main drivers pushing brands toward barrier papers. Today, many plastic-based packages end up in mixed waste because they cannot be sorted easily.

“When a material can go into the paper recycling stream, it changes the whole picture,” Duarte says. “It makes things easier for consumers. It helps retailers. And it prepares brands for future legal requirements. Recyclability is often the factor that convinces companies to take the next step. Furthermore, if barrier paper are disposed of in the “blue bag” they end up being recycled, which also brings along potentially massive CO₂ reductions.”

Bridging the gap between ordinary paper and plastics

For years, plastics have dominated flexible packaging because they offer barriers combined with easy sealing. Plain paper cannot provide the same level of protection. Glassine offers some/limited grease resistance, and therefore could be interesting solutions to some applications, but has no moisture barrier and cannot be sealed.

“Barrier papers give you the mix of sealability and protection that plastic films offer, but with the added benefit of being recyclable as mono-material in the paper waste stream. That is the key difference,” said Gustavo Duarte, Head of Business Development at Sappi Europe. “Moreover, for applications like stand-up pouches and bags, paper’s inherently higher stiffness vs plastics.” This opens space for paper-based solutions in segments long seen as too demanding for paper.

Working within a strict regulatory framework

Food packaging carries tight responsibilities. Sappi works with accredited external laboratories to ensure all materials meet food-contact requirements. Every ingredient entering Sappi’s mills must be approved for direct food contact.

“These certificates are essential,” Duarte says. “Customers rely on them for their own documentation and audits. We make sure the evidence is always available and up to date.”

Upcoming regulations, including the Packaging and Packaging Waste Regulation (PPWR), are also raising

expectations concerning recyclability. Sappi tests materials internally using CEPI/4evergreen methods before doing the external certifications, to identify potential issues early. And since Sappi expects that CEPI/4evergreen will be in high alignment with PPWR, this is already future proof for the upcoming European Technical Specification.

“This early testing helps us refine the papers quickly,” he says. “And it gives customers confidence that the material will meet not just today’s rules, but tomorrow’s as well.”

Responsible sourcing as a foundation for change

Traceability and responsible forest management play a central role in Sappi’s operations. The company follows FSC, PEFC and SFI certification systems across its global supply chain. In South Africa, Sappi manages 400,000 hectares of certified plantations. These forests supply local markets only.

“No wood travels from South Africa to Europe,” Duarte says. “Our European mills source wood from within roughly 150 kilometres of each site. It keeps supply chains short and transparent. And if a customer wants certified material, the delivery documents always carry the relevant claim.”

This approach is becoming increasingly important for brand owners, many of whom face growing pressure to trace every part of their supply chain.

Understanding the full cost of materials

At first glance, barrier papers can appear more expensive than certain plastics. But Duarte points out that the comparison is rarely straightforward. Plastics range from mono-materials to complex laminates that differ widely in price.

“You have to look at the complete cost picture,” he says. “Recycling fees can be higher for plastic laminates.In some countries, recyclable materials benefit from financial incentives.When you calculate everything – material cost, recycling fees, and any incentives – the result can favour paper-based solutions. It depends on the application, but companies are often surprised when they see the numbers clearly.”

A decade of development that positions Sappi as innovation leader

Sappi began producing barrier papers more than 10 years ago and has since built up a broad portfolio. The company uses dispersion-based technology that enables the papers to be recycled in the paper waste stream.

“We have the largest ranges of barrier papers available today,” Duarte says. “We don’t expect one grade to solve every demands. Instead of oversized standard products, we create papers that meet specific barrier requirements. It makes development faster and gives customers exactly what they need, that is both technically and commercially fit for purpose.”

He believes the broader shift toward paper-based flexible packaging will continue and intensify in the upcoming years, particularly as PPWR goes into force.

“This transition is unfolding step by step,” he says. “But the direction is clear. Consumers want packaging that support recycling and companies further want them to properly, protects the product/goods and works efficiently on their lines without major investment. Barrier papers can do all three. That’s why we see more interest every year.”