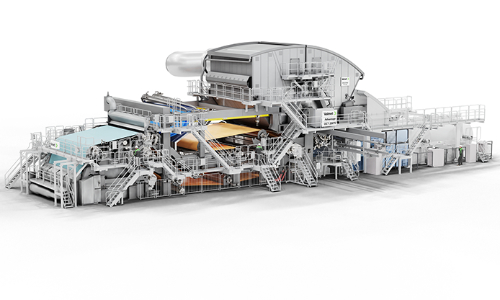

Hydrogen peroxide (H2O2) plays a vital role in the textile, pulp and paper, and chemical sectors, valued for its strong oxidising capabilities and its clean decomposition into water and oxygen. However, the industry’s prevailing production method, the anthraquinone auto-oxidation process, remains energy-intensive, highly centralised, and dependent on fossil-fuel-based hydrogen.

The HYPER consortium is paving a new, sustainable way for the sector by developing a modular, fully electrochemical route for decentralised H2O2 production.

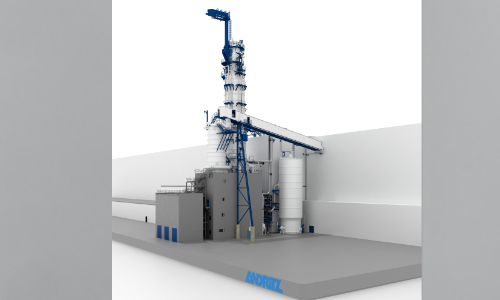

As the project heads into its concluding year, 2025 has delivered a major breakthrough: the latest milestone has been reached and the mini-plant is now operational, achieving TRL 4/5. This accomplishment reflects the outstanding work of all consortium partners.

Over the past year, the HYPER team has actively promoted the project at conferences across Europe and gathered in Hradec Králové, Czech Republic, for the seventh in-person consortium meeting. Following a first day dedicated to presentations and technical exchanges, the second day featured a visit to the InoTex industrial site. Partners were able to observe the TRL 4/5 mini-plant in full operation and witness firsthand the successful bleaching performance of electrochemically produced H2O2 on textiles .

The first HYPER webinar is taking place on 4 February 2026, with title “Electrochemical Pathways for a Greener Chemical Industry”. Jointly with Horizon Europe ELOXYCHEM project, it will bring together experts from research and industry to explore how innovative processes can support the transition towards a more sustainable and competitive European chemical industry.

With one year remaining in the project, 2025 marked a period of major advancement, setting the stage for an impactful final phase, towards the TRL 6 plant achievement.

Photo/Hyper