Sappi has expanded its functional packaging paper portfolio with a comprehensive series of heat-sealable solutions designed for converters, printers, and brands seeking fiber-based alternatives to plastic.

The Seal range – including Seal Silk, Seal G Silk, Seal Pure Silk, Seal Natural, Seal Light, and Seal Lucent – covers a wide spectrum of applications and sealing requirements, while ensuring easy integration into existing packaging lines. Offering basis weights from 44 to 110 g/m² with multiple finishes and features (including OBA-free and translucent options), this range is designed to help customers select the right weight for their packaging format, process, and visual requirements.

Many companies are facing pressure from new regulations, such as the EU Packaging and Packaging Waste Regulation (PPWR), rising customer expectations, and increased demand for recyclable packaging in global markets. Simultaneously, they require stable sealing results, high mechanical strength, and material compatibility with existing equipment. Total Cost of Ownership (TCO) is also a key factor, as paper-based solutions must remain competitive against plastic. The Seal range was developed to address these needs and facilitate the transition from plastic and composite structures to a monomaterial paper solution.

A paper range designed for your needs and flexibility

Each Seal paper grade is compatible with various production setups, printing methods, visual requirements, and sealing strengths. This allows you to choose the ideal paper for your production line, packaging format, or performance needs. Sappi also caters to specific requirements, such as OBA-free (optical brightener-free) grades or unique surface characteristics.

-

Seal Silk & Seal G Silk: Available from 50 to 110 g/m². They offer low-to-medium water vapor permeability (depending on the grade) and are compatible with flexographic and rotogravure printing.

-

Seal Pure Silk (67 g/m²): OBA-free for customers prioritizing a natural look or needing to meet specific compliance standards.

-

Seal Natural (95 g/m²): Offers high adhesion and excellent hot-tack properties.

-

Seal Light Gloss & Seal Light Natural: Available in 44 g/m² (Natural) and 54 g/m² (Gloss). These provide a lightweight solution for converters requiring low-grammage heat sealing.

-

Seal Lucent: Available in 44 and 54 g/m² for applications benefiting from translucency, such as window packaging or partial product visibility.

“We see that brands, converters, and printers are looking for reliable solutions to evolve their packaging without increasing risks or costs,” explains Michael Bethge, Sales Director Consumer Goods Packaging. “They need practical choices rather than a one-size-fits-all solution, along with technical support during the transition. The Seal range meets these expectations by offering customers a wide array of options.”

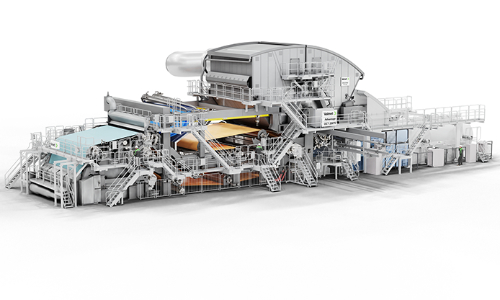

Reliable performance and exceptional print results

All Seal papers are engineered for uniform sealing and optimal print flow. Their high mechanical strength ensures stable processing and secure transport. These papers also deliver precise printing results, enabling brands to achieve a sharp and clear visual presentation on the shelf. Sappi supports its customers during trials, providing advice on sealing temperatures, dwell times, and machine settings.

Sappi has been developing functional papers for over 10 years, working closely with customers and OEMs (Original Equipment Manufacturers) for testing, material switching, and developing new packaging formats.

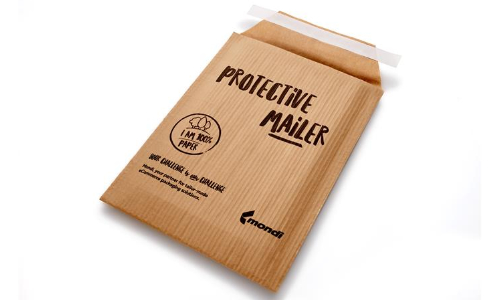

Primary and secondary packaging applications

The Seal range is suitable for primary and secondary packaging that does not require complex barrier structures and offers low-to-medium barrier performance. Examples include:

-

Multi-packs for confectionery (e.g., twists and napolitains).

-

Pillow bags, individual pouches, sticks, doypacks, and stand-up pouches.

-

Food and non-food products requiring secure closure without complex barriers.

Designed as a single material, these papers are recyclable in the paper waste stream where appropriate collection and sorting systems exist. They represent an ideal alternative to PE-coated papers and many plastic-based laminates.