The European paper sack and sack kraft paper industry has embarked on a journey to develop a pathway towards net zero. The current focus is on identifying the main contributors to the industry’s carbon footprint and key areas for decarbonisation. This work builds on a life cycle inventory and carbon footprint project that the industry initiated more than 20 years ago. Close cooperation among all stakeholders along the paper sack value chain will foster knowledge sharing and support the development of a pathway towards climate neutrality by 2050.

“Many EUROSAC and CEPI Eurokraft member companies are making excellent progress in their decarbonisation efforts – each of them with their own strategy,” explains EUROSAC president Alessandro Selmin.

“ As an industry, it is equally important to align collectively on the path towards net zero. Sustainability has always inspired innovation in our sector, and the development of a net zero pathway will encourage collaboration and drive us to continuously improve both our environmental impact and our packaging solutions for our customers.”

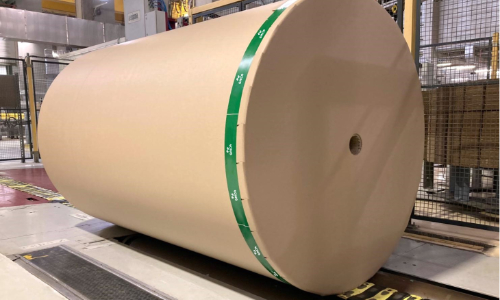

The net zero road map is a joint project of the European Paper Sack Research Group (ESG). For more than two decades, ESG has collected life cycle inventory (LCI) and carbon footprint data for sack kraft paper and paper sacks every three years. This data will serve as the backbone of the net zero pathway. At the end of 2025, the most recent data from 2024 will be incorporated.

Methodological approach

The calculations and targets for the net zero pathway are guided by the Greenhouse Gas Protocol (GHG Protocol)1 and Science-Based Targets initiative (SBTi)2. The focus is on identifying the main contributors to the carbon footprint at the industry level, rather than the product level. Priority areas for decarbonisation are defined both for sack kraft producers and paper sack converters, as they face different challenges. The road map covers the three emissions scopes defined by the GHG Protocol. The classification of activities into scopes is made from the perspective of an organisation and the scopes are related to the source and type of emission:

- Scope 1: Direct emissions from on-site fuel combustion (e.g. electricity, heat, steam) and process or fugitive emissions (e.g. wastewater treatment).

- Scope 2: Indirect emissions from purchased electricity, steam, heat or cooling.

- Scope 3: Other indirect emissions from purchased goods and services. Among others, Scope 3 can include emissions from purchased raw forestry products, pulp, films, inks, etc. as well as from outsourced transportation, landfill and incineration. Those are the hardest to influence from a company’s point of view.

Focus areas for reducing emissions

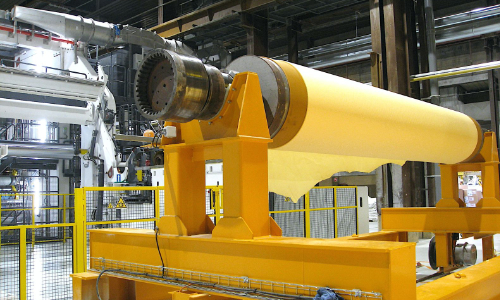

Among the most effective levers for reducing Scope 1 emissions are increasing energy efficiency and transitioning to cleaner energy sources, such as biofuels, solar, wind or hydropower at production sites. Scope 2 emissions can be reduced by purchasing electricity from low-carbon or renewable sources. For Scope 3, sourcing materials and services with lower emissions profiles is key. Scope 3 emissions are often the largest contributor to a company’s or an industry’s carbon footprint. This is reflected in the 2021 carbon footprint data for the European paper sack industry, where purchased sack kraft paper and plastic films are identified as the two main contributors of the carbon footprint of a paper sack.

Continuous improvement of CO2 footprint of paper sacks.

Looking into the historic data, the carbon footprint figures of the European paper sack and sack kraft paper industry show an impressive reduction between 2007 and 2021. The main improvements took place at the paper mills, where the fossil carbon impact per tonne of sack kraft paper decreased by approximately 26% – from 570 kg CO2e to 421 kg CO2e. The reasons for that are predominantly fewer emissions from net purchased grid electricity and from the combustion of fossil fuels consumed by the mills. For sack converters, these reductions are relevant as they count as Scope 3 emissions. Per paper sack, the carbon footprint figures show a 28% improvement – from 118 g CO2e per sack in 2007 to 86 g CO2e per sack in 2021. This progress demonstrates how decarbonisation measures in the supply chain already deliver meaningful results and paved the way for the net zero pathway project. More examples of decarbonisation projects from the industry.

Collaboration for the better

The EUROSAC and CEPI Eurokraft associations bring together sack kraft paper producers, sack converters and manufacturers of films, adhesives and machinery.

“We benefit from already working very closely together,” explains Selmin. “This strong collaboration empowers us to drive positive change across the entire paper sack value chain and makes it easier to address Scope 3 emissions collectively.”

A recent example is the joint product development between plastic film producer W. Gröning and kraft paper producer Billerud, resulting in a reduced-carbon-footprint solution. Their Future-Proof Paper Sack for Low-Carbon Cement combines ultra-breathable, semi-extensible sack kraft paper with an HDPE film containing 35% post-consumer recycled (PCR) content. Another example of a cross-industry collaboration is the Construction Goes Circular project which started in Spain. With over 70 companies and 180 construction sites, it boosts the recycling of paper sacks and other construction materials, helping cut emissions in both the paper sack industry and the construction sector.

“Projects and innovations like these show that our industry is committed to developing a clear road map towards net zero,” says Selmin. “Together, we can lay the foundation for real change.”