In the tissue sector, having reliable, efficient, high-performing and sustainable production lines is essential to remain competitive over the long term. In this context, relying on an OEM capable of providing structured support throughout the entire lifecycle of the plant is a strategic advantage. Valmet’s Lifecycle Services fully address this need, supporting customers from the start-up phase through to the implementation of advanced solutions. This comprehensive approach ensures long-term asset performance by fostering continuous technological evolution, maximising operational efficiency and delivering consistently high-quality output.

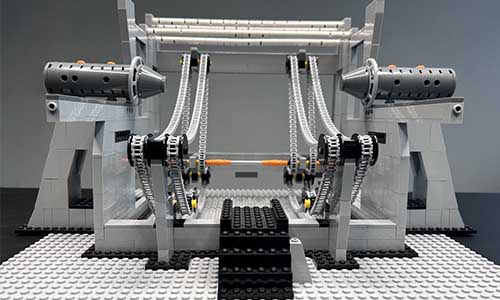

Valmet’s expertise in the tissue sector is built on accrued field experience, with over 18,000 converting lines installed worldwide. This unique wealth of application knowledge, combined with a constant focus on customer needs, has led to the development of a structured and cross-functional offering. A catalogue of over 180 products covers all lines, with dedicated solutions for Converting Roll, Converting Fold and Packaging machines, as well as digital solutions available for any type of machine. Valmet’s approach to plant lifecycle management is expressed through two service models: standard solutions, ready for implementation and custom interventions, designed to meet the specific needs of tissue producers.

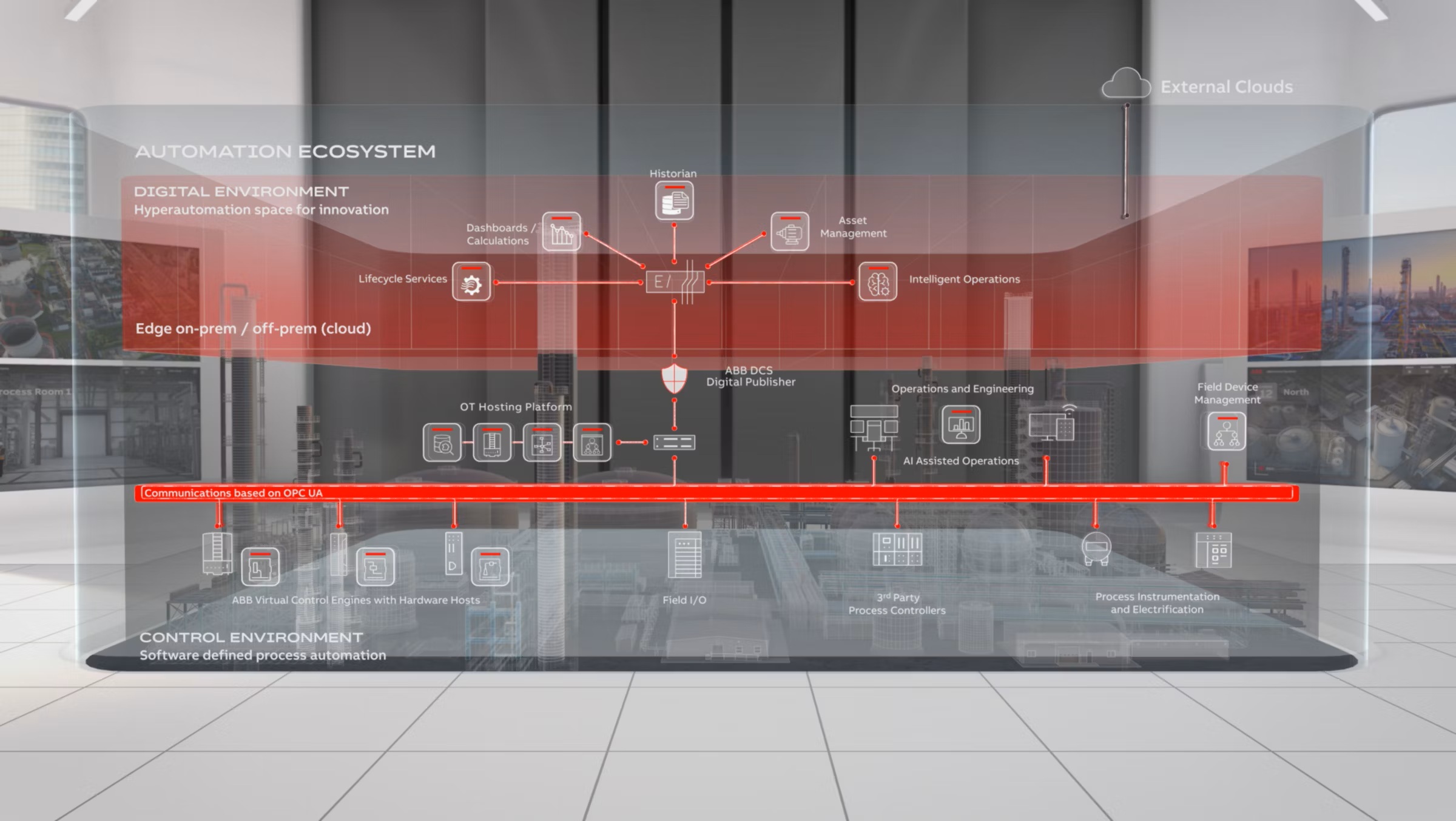

Standard Improvement Projects are consolidated solutions, ready to be implemented across a wide range of machines with similar configurations. These include, for example, operator panel replacement, connectivity solutions, remote assistance, advanced sensors, glue filtering and management, the installation of cameras and thermocameras and fire mitigation systems. On the other hand, Custom Improvement Projects entail dedicated engineering work to meet the needs of plants with specific configurations: from the replacement of motors, drives, PLCs and axis control systems, to the upgrade of safety systems and electrical panels to machine-mounted equipment, to the introduction of new features enabled by the latest Valmet technologies.

Standard Improvement Projects are consolidated solutions, ready to be implemented across a wide range of machines with similar configurations. These include, for example, operator panel replacement, connectivity solutions, remote assistance, advanced sensors, glue filtering and management, the installation of cameras and thermocameras and fire mitigation systems. On the other hand, Custom Improvement Projects entail dedicated engineering work to meet the needs of plants with specific configurations: from the replacement of motors, drives, PLCs and axis control systems, to the upgrade of safety systems and electrical panels to machine-mounted equipment, to the introduction of new features enabled by the latest Valmet technologies.

“Our Improvement Projects are the result of an ongoing dialogue with our customers and are structured around six strategic areas that reflect their operational priorities: safety, sustainability, efficiency, maintenance, performance and modernization,” stated Ian Arrighi, SER Product Specialist at Valmet who concludes “This approach allows us to deliver targeted interventions that improve OEE, stabilise performance and keep machines running efficiently, avoiding obsolescence and ultimately extending the lifecycle and maximising Total Cost of Ownership (TCO).”

The process for managing client requests is designed to ensure maximum transparency, efficiency and reliability. Each case is approached methodically, beginning with a preliminary technical assessment, an evaluation of the plant’s condition and the development of a detailed proposal. All analysis results and evaluations are shared through a comprehensive document outlining expected benefits, timelines, costs and operating procedures. Once the proposal is finalized, Valmet oversees all phases of execution: from design and implementation to the final verification of performance and compatibility with the existing line. This end-to-end process allows for accurate planning and ensures tangible results aligned with the specific production context. Lastly, the Customer Service Portal is a key element: through a dedicated platform, customers can access an always up-to-date overview of available products and request information from their sales representative directly through the browser.

Maurizio Rossi, SER Sales Specialist & EOL Team Leader adds “The benefits for companies that adopt Valmet’s Upgrades are both measurable and significant. Our customers have seen an increase in Overall Equipment Effectiveness (OEE) of up to 10%, along with a marked reduction in downtime and clear improvements in product quality. These results are also accompanied by higher operator safety and a strong focus on sustainability, thanks to targeted solutions that help reduce energy consumption and environmental impact.”